The 5G Final Tier 4 (FT4) Specialty Series now brings a narrow, ultra-narrow, and low-profile option to specialty applications.

The 5GV Series is built to operate in vineyards with a minimum working width of 108.8 cm (42.8 in.) from rear tire to rear tire. The 5GV Series cab, with an overall width of 108.1 cm (42.6 in.), is designed to pass between narrow vineyard rows. The 5GN features an extra- wide cab of 127.5 cm (50.2 in.). The 5GL series is manufactured with orchardists in mind. This low-profile tractor has an approximate height of 135.89cm (53.5 in.) and width of 152.4cm (60 in.) (depending on tire configuration), which makes it ideal for operating in orchards that are laden with heavy fruit.

The two-door cab on the 5GN and 5GV models offers the operator yet another convenience of entering and exiting from either side. With a distance of 560 mm (22.1 in.) between the right- and left-hand side consoles and a play of 285 mm (11.2 in.) between seat and steering wheel, the 5G Series provides one of the roomiest cabs in the specialty tractor market.

Overview of minimum working widths

Overview of minimum working widths5G Specialty Series basic feature overview:

| Feature overview | 5GN | 5GV | 5GL |

| 100 hp (74 kW), 4-cylinder / 3.4 L (0.9 gal.) | 5100GN | N/A | N/A |

| 90 hp (63 kW), 4-cylinder / 3.4 L (0.9 gal.) | 5090GN | 5090GV | N/A |

| 75 hp (55 kW), 4-cylinder / 3.4 L (0.9 gal.) | 5075GN | 5075GV | 5075GL |

| Two-wheel drive (2WD) / four-wheel drive (4WD) | Only 4WD | Only 4WD | Only 4WD |

| Cab / open operator station (OOS) | Available | Available | Only OOS |

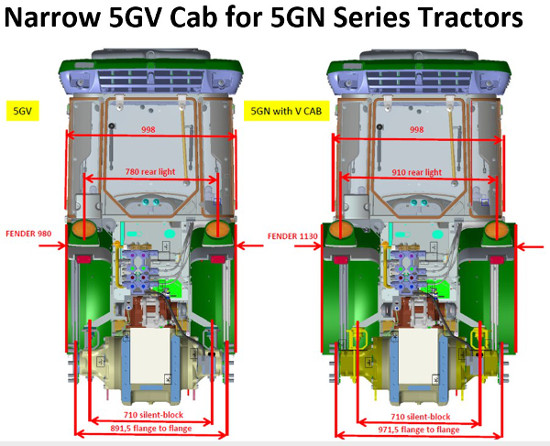

5GV cab on 5GN Tractor

5GV cab on 5GN TractorThe 5G Series has also expanded its platform offerings to include a 5GV cab on a 5GN Tractor. This option combines the fit of 5GV with the wider stance of a 5GN, providing excellent stability paired with the narrowest cab offering available in the 5G portfolio.

Performance: tailored to fit – matching narrow widths and low heights to producers’ high value crop applications.

The 5GN models have an optional auxiliary fuel tank available, which increases the fuel tank capacity by up to 38 percent on the 5075GN and up to 33 percent on the 5090GN and 5100GN.

The increased capacity allows for more productive time in the field with fewer stops for refueling.

| Machine | Code | Fuel tank capacity | Code | Auxiliary tank capacity |

| 5075GN | Base | 86 L (22.7 gal.) | 8313 | 28.4 L (7.5 gal.) |

| 5090GN | Base | 73 L (19.3 gal.) | 8313 | 28.4 L (7.5 gal.) |

| 5100GN | Base | 73 L (19.3 gal.) | 8313 | 28.4 L (7.5 gal.) |

Auxiliary fuel tank

Auxiliary fuel tankThe 5G Specialty Series Tractors are equipped with powerful FT4 diesel engines.

All GN, GV, and GL models are equipped with a robust FPT Industrial 4-cylinder, 3.4-L (207.5-cu in.) displacement engine that offers real versatility and performance for all kinds of specialty operations.

| Engine overview | 5GN | 5GV | 5GL |

| 74.6 kW (100 hp), 4-cylinder / 3.4 L (207.5 cu in.) | 5100GN | Not available | Not available |

| 67.1 kW (90 hp), 4-cylinder / 3.4 L (207.5 cu in.) | 5090GN | 5090GV | Not available |

| 55.9 kW (75 hp), 4-cylinder / 3.4 L (207.5 cu in.) | 5075GN | 5075GV | 5075GL |

Supporting the narrow dimensions of the 5GV Series

The narrow width of the 5GV Series requires a compact engine solution. The compact 3.4-L (207.5-cu in.) engine supports the envelope of the 5GV Series entering super narrow vineyards as well as the turning radius at the end of a row.

Performance - made to measure

The engine ensures high productivity under tough working conditions. With a torque of 401 Nm (295.7 lb-ft) for the 74.6-kW (100-hp) model, the engine ensures the optimal performance for versatile operations.

John Deere value:

Performance: the powerful FT4 engines support the narrow machine envelope of the 5G Specialty Series and offer a high torque at rated rpm, which provides a high performance.

The 5G Series Tractors are heavy-duty utility tractors in two narrow chassis widths. Heavier gross vehicle weight means more down force to keep implements in the ground. Heavier equipment also leads to improved traction and performance in the field. The 5G Series Tractors have the weight to power through tough jobs.

| Machine | Four-wheel drive (4WD) rollover protective structure (ROPS) | 4WD cab |

| 5075GV | 2530 kg (5577 lb) | 2745 kg (6051 lb) |

| 5090GV | 2530 kg (5577 lb) | 2745 kg (6051 lb) |

| 5075GN | 2660 kg (5864 lb) | 2975 kg (6558 lb) |

| 5090GN | 2660 kg (5864 lb) | 2975 kg (6558 lb) |

| 5100GN | 2660 kg (5864 lb) | 2975 kg (6558 lb) |

| 5075GL | 2670 kg (5886 lb) | No cab option |

Regular service and maintenance are essential to the performance, productivity, and longevity of the tractor.

All items in the daily service schedule can be performed without the use of tools:

NOTE: Always refer to the operator’s manual for complete maintenance and service recommendations.

The John Deere 5G Series provides an outstanding total hydraulic system flow of 126.4 L/min (33.4 gpm) with an optional third hydraulic pump.

This hydraulic system ensures excellent hydraulic performance and capacity:

Hydraulic performance | 5075GV | 5090GV | 5075GN | 5090GN | 5100GN | 5075GL |

| Steering and transmission | 29.9 L/min (7.9 gpm) | |||||

| Second pump - SCV and hitch | 66.6 L/min (17.6 gpm) | |||||

| Third pump - rockshaft | 29.9 L/min (7.9 gpm) | |||||

| Total hydraulic flow | 126.4 L/min (33.4 gpm) | |||||

The heavy-duty 3-point hitch design on the 5G Series provides a standard maximum lift of 2590 kg (5,710 lb) at the ball ends. An optional additional lift cylinder is available for the 5GN Series, which increases the maximum lift capacity by 510 kg (1,124 lb) to 3100 kg (6,834 lb) at the ball ends.

Hooking up implements is quick and simple with the standard Category 2 3-point hitch on the 5GN. Hooking up implements that require Category 1 or Category 1N is also possible and requires very little time with the 5GV and 5GL.

Optional extra lift capacity shown on the 5GN photo

Optional extra lift capacity shown on the 5GN photo| Code | Description | Information | Availability |

| 8490 | Additional lift cylinder | Includes additional lift cylinder (maximum lift capacity at ball ends: 3100 kg [6,834 lb]) | 5GN |

| 4130 | Fixed ball ends | 3-point hitch with fixed ball ends for draft links | 5GN, 5GV |

| 4131 | Adjustable ball ends | 3-point hitch with adjustable ball ends for draft links | 5GN, 5GV |

| 4132 | Adjustable quick couplers | 3-point hitch with adjustable quick couplers for draft links | 5GN, 5GV, 5GL |

| 4151 | Hydraulic lift rod | Hydraulically adjust lift arm to tilt or level implement | 5GN, 5GV, 5GL |

| 4152 | Mechanical lift rod | Mechanically adjust lift arm to tilt or level implement | 5GN, 5GV, 5GL |

Lift rods

Lift rodsJohn Deere value

Performance: higher lift capacity for a wider variety of implements and strong performance means real versatility.

The 5G Series comes standard with a 24 forward/12 reverse (24F/12R) PowrReverser™ transmission. The 24F/12R transmission provides 24 forward speeds and 12 reverse speeds for transport speeds of up to 40 km/h (24.9 mph). The transmission provides convenient Hi-Lo and declutch push-button controls. The Hi-Lo feature benefits operators who frequently transport their tractors from field to field or find themselves in bog-down situations during rear power take-off (PTO) work.

Users can push the rabbit button (high) without having to depress the clutch to get an increase in speed. They can also push the turtle button (low) to get a decrease in speed, similar to downshifting or engine braking without having to grab another gear. The PowrReverser transmission has a built-in engagement override valve for additional safety. This valve requires the clutch pedal to be depressed one time after each engine start before the transmission will begin to operate normally, giving the operator another opportunity to put all focus on the tractor. A neutral start switch requires the PowrReverser lever to be in the neutral position to start the engine.

Gear-shift lever with Hi-Lo selectors

Gear-shift lever with Hi-Lo selectors| 24F/12R PowrReverser | |

| Speed (km/h) | 0.5 to 40 km/h (0.3 to 24.9 mph) |

| Creeper range | Yes |

| Configuration | Four-wheel drive (4WD) |

| Clutch type | Multi-disc wet clutch |

| Clutching required to shift | No |

| Reverser | PowrReverser |

| Hi-Lo | Electrohydraulic |

| Mechanical front-wheel drive (MFWD) engagement | Electrohydraulic, if MFWD option installed |

| PTO engagement | Electrohydraulic |

| Differential lock engagement | Electrohydraulic |

Compare the specifications of up to 4 models

| Key Specs | 5100gn-narrow-series-tractor Current Model |

|---|---|

| Engine description | 3.4L Fiat® Powertrain Technologies |

| Engine displacement | 4 cylinder: 3.4 L 207 cu in. |

| Rated engine power | 74.6 kW 100 hp |

| Rated PTO power (hp SAE) | 64.9 kW 87 hp |

| Transmission type | 24F/12R PowrReverser, EH Hi-Lo |

| Hydraulic pump rated output | Standard: 96.5 L/min 25.5 gpm Optional: 126.4 L/min 33.4 gpm |

| Rear hitch category (SAE designation) | Category 1/Category 2 |

| Base machine weight | OOS: 2660 kg 5864 lb Cab: 2975 kg 6558 lb |

| Maximum PTO power | |

| Maximum engine power | |

| Engine specifications | |

| Description | 3.4L Fiat® Powertrain Technologies |

| Engine type | |

| Engine family | FPTF34 |

| Rated speed | 2300 rpm |

| Aspiration | Turbocharged |

| Cylinders liners | Wet sleeved |

| Emission level | Final Tier 4 |

| After treatment type | Diesel Oxidation Catalyst (DOC) and Selective Catalyst Reduction (SCR) |

| Displacement | 4 cylinder: 3.4 L 207 cu in. |

| Engine performance | |

| Rated power | 74.6 kW 100 hp |

| Rated PTO power (hp SAE) | 64.9 kW 87 hp |

| Power boost | |

| Engine peak torque | |

| PTO torque rise | |

| Intelligent Power Management (available in transport and/or mobile PTO applications) | |

| Maximum PTO power | |

| Maximum engine power | |

| Transmission | |

| Type | 24F/12R PowrReverser, EH Hi-Lo |

| Reverser | Yes |

| Clutch; wet/dry | Wet |

| Creeper | Yes |

| Hydraulic system | |

| Type | Open Center |

| Pump rated output | Standard: 96.5 L/min 25.5 gpm Optional: 126.4 33.4 gpm |

| Available flow at a single rear SCV | 41.6 L/min 11 gpm |

| Available flow at front SCVs | |

| Number of rear selective control valves (SCVs) | Standard: 2 Optional: 4 |

| Number of mid selective control valves (SCVs) | |

| Number of front selective control valves (SCVs) | |

| Joystick SCV control | |

| SCV control | Mechanical |

| Rear hitch | |

| Hitch draft control load sense type | Mechanical |

| Remote control valves available | |

| Hitch category (SAE designation) | Category 1/Category 2 |

| Maximum lift capacity behind lift points | 2549 kg 5620 lb |

| Sensing type | Top Link Draft Sensing |

| Rear axle differential lock | |

| Lift capacity at standard frame | |

| Drawbar | |

| Drawbar category | Extendable |

| Maximum vertical load | |

| Rear power take-off (PTO) | |

| Type | Standard: 540/540E |

| Engine rpm (at rated PTO speeds) | 540 at 1938 rpm 540E at 1648 rpm |

| PTO actuation | Electrohydraulic |

| Ground speed PTO option availability | |

| Multispeed PTO option availability | |

| Front hitch | |

| Category | |

| Electric power | |

| Standard lift capacity | |

| Front power take-off (PTO) | |

| PTO speed | |

| Rear axle | |

| Type | Carraro Drivetech |

| Final drive type | Three point inboard planetary drives |

| Differential controls | Multi disk oil cooled design |

| Axle type | Flanged |

| Brakes, type and control | Multi-disc rear braking |

| Rear differential lock | Electrohydraulic |

| Load rating | |

| Front axle | |

| Type | Carraro Drivetech |

| Front axle differential lock | Self Locking Differential |

| Load rating | |

| Tires | |

| Front | 7.50R16 |

| Rear | 280/70 R18 |

| Wheel tread range | |

| Turning radius with brakes | |

| Turning radius without brakes | 3627 mm 11.9 ft |

| Steering | |

| Type | Dynamic Load Sensing, Hydrostatic, Flow Metering |

| Electrical system | |

| Alternator size | 120 amp |

| Battery options | |

| Total cold cranking amps | |

| Type of bulb in beacon (Halogen, Zenon, LED) | |

| Type of bulb in headlight (Halogen, Zenon, LED) | |

| Working lights | |

| dB(A) rating for backup alarm | |

| Operator station | |

| Rollover protective structure, OOS | Rigid - foldable - telescopic Rigid, front folding Platform - flat/straddle Straddle Gearshift location - console/floor Floor Yes |

| Seat | OOS: standard: COBO MT SC74 M200 Optional: COBO MT SC74 M97 Cab: standard: COBO MT SC74 M200 Optional: GRAMMER MSG93/511 |

| Cab suspension | |

| Instructional seat | |

| Display | |

| Radio | |

| Inner cab volume | |

| dB(A) rating | 82 |

| Cab glass area | |

| Front visibility | |

| Safety glass rating | |

| Dimensions | |

| Wheelbase | 2098 mm 82.5 in. |

| Overall length | 4319 mm 170 in. |

| Drawbar clearance | Min. 254 mm 10 in. Max. 289 mm 11.3 in. |

| Front axle center | Min. 254 mm 10 in. Max. 289 mm 11.3 in. |

| Approximate shipping weight, Open;Cab | |

| Overall height | |

| Weight | |

| Base machine weight | OOS: 2660 kg 5864 lb Cab: 2975 kg 6558 lb |

| Maximum ballast level | |

| Maximum permissible weight | 4200 kg 9259.41 lb |

| Capacities | |

| Crankcase oil volume | |

| Fuel tank | Standard: 73.1 L 19.3 U.S. gal. Optional: 101.4 L 26.8 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | |

| Cooling system | |

| Transmission-hydraulic system | |

| Serviceability | |

| Interval for engine oil change | 500 |

| Interval for hydraulic/transmission oil change | 750 |

| Interval for engine coolant change | |

| Loaders | |

| Loader | |

| Lift capacity at full height | |

| Maximum lift height | |

| Precision AG | |

| Guidance | |

| Telematic | |

| Remote diagnostics | |

| Miscellaneous | |

| Country of manufacture | |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Tracks | |

| Drive type | |

| Midrollers | |

| Track width | |

| Tread spacing |

The optional beacon light is available ex-factory.

The beacon light is mounted at the rear of the cab roof and can be folded backward to prevent breakage in areas with low overhead clearance.

On open operator station (OOS) tractors, the beacon light is mounted in the center of the rollover protective structure (ROPS).

If the tractor is ordered ex-factory without a beacon light, the cab still includes the basic wiring preparation. The missing components like the in-cab switch, mounting bracket, and light can be ordered with the following field-installation kit.

The optional deluxe cab seat provides an excellent driving position and superior operator comfort for long working days in rough terrain. It has a wide seat and backrest with wrap-around padding to hold the operator in the seat when travelling over rough or sloped terrain.

The seat features:

The optional beacon light is available ex-factory.

The beacon light is mounted at the rear of the cab roof and can be folded backward to prevent breakage in areas with low overhead clearance.

On open operator station (OOS) tractors, the beacon light is mounted in the center of the rollover protective structure (ROPS).

If the tractor is ordered ex-factory without a beacon light, the cab still includes the basic wiring preparation. The missing components like the in-cab switch, mounting bracket, and light can be ordered with the following field-installation kit.

Cab carbon air filter location

Cab carbon air filter locationThe improved carbon filtration system reduces the amount of dust or pollen entering the cab for a more comfortable work environment. The carbon air filters are located on either side of the cab roof and are easily accessed without requiring tools.

The optional rear windscreen wiper with washer provides single speed wiping of the rear windscreen in wet weather to maintain good rearward visibility to implements or trailers and is available on the 5GN and 5GV cab tractors.

To protect the tractor and operator from dust and debris, various 2WD front fenders for the 5GN and 5GV Series are available ex-factory and as attachments:

Various front fender options are available for the 5GN and 5GV Series ex-factory and as attachments to protect the cab from debris while turning.

Stationary front fenders — chassis-mounted front fenders which are fixed

Rear fender extensions are available for the 5GN, 5GV, and 5GL Series ex-factory and as attachments to protect the cab from debris.

Rear fender extensions are available for the 5GN, 5GV, and 5GL Series ex-factory and as attachments to protect the cab from debris.

© COPYRIGHT 2025 LEGACY EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By