*Must pre-order a new John Deere 1 - 4 Series tractor in order to be eligible for the Free pickup and delivery for life offer. Must be within 30 miles of a Legacy Equipment location. Offer is valid on the timespan the original customer who preordered the John Deere Tractor owns it. Non-transferable. Some restrictions may apply. See Legacy Equipment for complete details.

4R Tractor

4R Tractor

The bold styling of the 4M and 4R Tractors provide an attractive and functional appearance similar to that of the larger agricultural tractors. Benefits of this styling include:

The result gives the tractor a distinctive appearance and feel.

NOTE: If the tractor is equipped with an optional field-installed vertical exhaust, exhaust pipe must be removed before opening and closing the hood of the tractor.

Powerful Yanmar engine

Powerful Yanmar engineThe Yanmar diesel engine has a high-torque reserve that provides plenty of power under heavy load.

This 4-cylinder engine features lower levels of exhaust emissions and reduced noise levels. It meets EPA Final Tier 4 (FT4) emission standards.

Model | Number of | Engine | Aspiration | Rated | Gross engine | Gross engine ps* | PTO hp |

4 | 2.2 L | Natural | 42.5 | 43.1 | 32.5 | ||

4052M/R | 4 | 2.1 L | Turbocharged | 50.8 | 51.5 | 39.9 | |

4066M/R | 4 | 2.1 L | Turbocharged | 2600 | 65.0 | 65.9 | 52.0 |

The electronic control unit (ECU) provides optimum fuel control and accuracy. ECU monitors and controls the engine. It continuously monitors engine conditions and adjusts the fuel delivery accordingly to ensure optimum performance and emissions.

The new engine comes with an after treatment system. The system operates automatically. The exhaust filter consists of a diesel particulate filter (DPF) which captures particulate matter (PM) contained in the exhaust gas. Using a natural cleaning process, most of the PM trapped in the exhaust filter is eliminated by the heat of the exhaust stream generated by normal use. In situations of low temperature, engine speed or load factor, an active cleaning cycle is initiated. In this cleaning cycle, the exhaust gas temperature is raised by injecting additional fuel during the exhaust stroke of normal vehicle operation to the diesel oxidation catalyst (DOC).

After many hours of use, the exhaust filter may require an ash removal service.

NOTE: *As compared to engines not using CRS technology.

Depending on the load that the tractor is under, as well as ambient temperature, humidity, and engine speed, the DPF may build up with particulate matter, thus requiring cleaning. Filter cleaning is determined by one of three conditions:

Once one of the three conditions has been met, filter cleaning will occur.

There are three different types of filter cleaning processes:

Passive filter cleaning

Passive filter cleaning occurs naturally when the engine is generating enough heat to oxidize particulate matter. This automatic process occurs continuously during normal operating conditions. No tractor icons or symbols appear on the display during passive filter cleaning.

NOTE: Passive filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

Active filter cleaning

If conditions (temperature, load, or speed) for passive filter cleaning cannot be achieved, then PM is removed using active filter cleaner.

To achieve the required conditions, exhaust temperature management (ETM) manages the initiation and duration of active filter cleaning. ETM can adjust numerous engine parameters and/or inject a small quantity of fuel into the exhaust stream for a short duration. The fuel turns to vapor and chemically reacts with the catalysts in the DOC to create heat to oxidize PM.

It is important to note that at no time is the fuel in the DOC/DPF ignited, and there is no flame within the DOC/DPF.

Like passive filter cleaning, active filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

Parked filter cleaning

In some instances where passive and active filter cleaning have not fully cleaned the PM from the system, a parked filter cleaning may need to take place. Most likely, the only time a parked filter cleaning will need to occur is when automatic filter cleaning has been disabled for an extended period of time and multiple warnings to engage filter cleaning were ignored or if the tractor has been used during light load conditions. Additionally, when the automatic filter cleaning process has been deliberately interrupted multiple times, or if active filter cleaning has failed numerous times due to a failed component, a parked filter cleaning may be requested. In these rare instances the operator will have to park the tractor and start the filter cleaning process.

The parked filter cleaning process needs to be activated based on usage and operation of the tractor. The process will take approximately 30 minutes. See operator’s manual for more details.

This system constantly monitors the soot level of the tractor, making sure the tractor is always in peak performance condition. This ensures high performance at all times.

NOTE: Number of hours since last regeneration and soot level percentage viewable on LCD display.

Key features of the engine are:

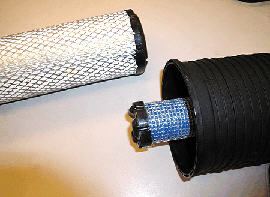

Dry-type air cleaner

Dry-type air cleaner

Yanmar is a trademark of Yanmar Company Limited.

PowrReverser transmission lever

PowrReverser transmission leverThe 12/12 PowrReverser transmission is available on the 4M and 4R Tractors.

The PowrReverser transmission offers a hydraulically shifted forward-to-reverse transmission. This allows for clutchless shuttle shifting between forward and reverse with one lever for quick and easy direction change.

The PowrReverser transmission features a hydraulically actuated wet clutch. Two multi-disk clutch packs (one forward and one reverse) are hydraulically engaged when the directional (reverser) lever is placed in either the forward or reverse position.

Each clutch pack consists of three large, 5-in. diameter clutch disks that operate in oil and are oil-cooled, allowing excellent heat dissipation and extended clutch life.

Forward/reverse clutches

Forward/reverse clutches

Key features of the PowrReverser transmission:

Helical-cut gears

Helical-cut gears

The tractor is available with a three-range electronic hydrostatic (eHydro) transmission.

Danfoss® supplies both the pump and motor. This ensures that the components are matched to each other, providing maximum efficiency.

The electronic hydrostatic transmission is ideally suited for jobs where productivity is a must, such as loader or mower applications.

Twin Touch™ foot controls allow the operator to select both directions of travel and speed with a touch of the toe.

Key features of the eHydro transmission:

Danfoss eHydro transmission

Danfoss eHydro transmission

Danfoss eHydro transmission is used for reliable operation. Durability features include:

Safety features of the eHydro transmission include:

Twin Touch foot controls

Twin Touch foot controls

John Deere's Twin Touch foot controls offer several key advantages over competitive hydro model tractors.

The eHydro convenience controls have been integrated into a single module. Combining features such as SpeedMatch™ LoadMatch™, MotionMatch™ eThrottle™ and automotive style cruise control pulls the maximum efficiency out of the eHydro transmission tractors. All of these features are standard on the 4R models, and deliver customers an easier and more comfortable experience.

eHydro convenience control module

eHydro convenience control module

| Press button to active/deactivate eThrottle. When eThrottle is activated, depression of the travel pedal increases engine RPM and tractor speed. |

| Press button to active/deactivate LoadMatch. When LoadMatch is activated, engine will not stall during heavy load applications. |

| Press button to activate/deactivate SpeedMatch. When SpeedMatch is activated, operator is able to set the desired maximum travel speed. |

| Press button to activate/deactivate cruise control. When cruise control is activated, operator is able to set cruise speed. |

| Press button to set cruise speed, or to decrease cruise/set max speed. |

| Press button to resume set cruise speed, or to increase cruise/set max speed. |

| MotionMatch - longer accelerate and decelerate distances. |

| MotionMatch - shorter accelerate and decelerate distances. |

eThrottle

eThrottle indicator

eThrottle indicator

Press a button to activate/deactivate eThrottle™. When eThrottle is activated, depression of travel pedal increases engine rpm and tractor speed simultaneously. This provides the operator with comfort and convenience as well as fuel economy.

Cruise control indicator

Cruise control indicator

An automotive-style cruise control is standard equipment on the 4R Series Tractors. Cruise control is electronically engaged and disengaged and is located on the right-hand operator console.

LoadMatch indicator

LoadMatch indicator

LoadMatch is a standard feature on the 4R Series Tractors.

If torque requirements increase significantly, the transmission will reduce the tractor's drive speed to compensate for the increased load on the transmission, maximizing torque to drive wheels and minimizing stalls.

Controls automatically adjust LoadMatch compensation depending on the tractor’s application. PTO applications require less engine speed fluctuation, therefore adjusting the amount of droop depending on PTO speed. This adjustment increases efficiency and optimizes engine speed and torque output based on tractor application.

While typically left on, LoadMatch can be turned off with the right-hand console controls.

MotionMatch™

The MotionMatch, standard on the 4R Series Tractors, is located on the right-hand console. It offers seven settings for adjusting the rollout or decelerating when the pedal is released.

MotionMatch indicator

MotionMatch indicator

Longer accelerate and decelerate distances.

MotionMatch indicator

MotionMatch indicator

Shorter accelerate and decelerate distances.

SpeedMatch indicator

SpeedMatch indicator

SpeedMatch, standard on the 4R Series Tractors, further enhances the eHydro cruise control functions by allowing the operator to preset maximum speed. Once this feature is engaged, the operator must stroke the travel pedal fully to meet the operator’s preset speed and press the Set button to lock the speed. From there, the operator can use the automotive-style cruise controls to adjust speed. This function will improve accuracy and safety, particularly at lower travel speed applications.

Rotary tilling or spraying applications are examples of where SpeedMatch can be applied. SpeedMatch will work in both the forward and reverse set speeds.

NOTE: Automotive-style cruise control and SpeedMatch can be used in conjunction with LoadMatch to maximize productivity.

Danfoss is a trademark of Danfoss Incorporated.

Easy entry and exit from the operator's station

Easy entry and exit from the operator's station

The operator's station is designed for easy entry and exit from the tractor.

Conveniently placed brake pedals, as well as repositioned operator controls, provide for a clean and flat platform design giving the operator plenty of legroom.

Comfortable and convenient design

Comfortable and convenient design

Key features of the operator's station include:

Adjustable, tilt steering wheel

Adjustable, tilt steering wheel

Left-side step

Left-side step

Adjustable scissor-type suspension seat

Adjustable scissor-type suspension seat

ComfortGard cab

ComfortGard cab

John Deere ComfortGard cab tractors are the most comfortable, quiet, and easy-to-use cab tractors available. This premium solution was developed using extensive customer research and validation, tools, and some of the most advanced design techniques available.

The following John Deere ComfortGard cab tractor models are available:

Cab tractors are designed for those who demand superior performance:

Whether using a loader to move dirt or remove snow or doing a variety of other tasks like mowing, tilling, rotary cutting, or light hay work, the cab tractors have the versatility and muscle to get the job done, all while protecting the operator from the elements.

State-of-the-art design

State-of-the-art design

Operators are sure to appreciate what this cab has to offer – beginning with an isolated cab. These cabs are designed with robust mounting points integrated into the rollover protective structure (ROPS) with a unique offset mounting design that provides an ultra-quiet ride.

A 4-post ROPS design, carefully laid-out interior, and fuel tank located under the left rear side of the operator's platform provide a full 360 degrees of visibility:

Operators are well-protected from the elements with a high-performance climate-control system providing heating and air conditioning.

Superior operator comfort

Superior operator comfort  Optional radio kit

Optional radio kitSeveral features are integrated into the design of the cab that deliver superior operator comfort and visibility:

Right-hand control panel

Right-hand control panel  Side-post mounting bosses

Side-post mounting bosses Installing rear window removable plug

Installing rear window removable plug Rear window removable plug installed

Rear window removable plug installedA deluxe cloth seat with a retractable seat belt is in base equipment:

Air-suspension seat

Air-suspension seat

An air-ride seat is standard on the 4066R Cab Tractor and is available as an option on the 4044R and 4052R Cab models. This seat is designed to provide an air cushion for vertical-seat travel which provides maximum operator comfort in any terrain.

The deluxe air-ride seat is a field-installed option on the 4044R and 4052R Cab Tractor.

Seat features:

The optional field-installed air-suspension kit requires the existing standard seat to be reused when installed.

NOTE: The deluxe two-piece seat top may be ordered through Parts.

Key benefits include:

Lighting equipment

The base lighting package for cab tractors includes:

Adjustable rear work lights

Adjustable rear work lights Optional lighting includes:

Jensen is a trademark of ASA Electronics Corporation. iPod is a trademark of Apple Incorporated. SIRIUS is a trademark of SIRIUS XM Radio Inc.

Safety is designed into all 4M and 4R Series Tractors.

The hitch assist feature allows the operator to creep the tractor backward/forward while standing behind the tractor. Engaging and operation includes the following steps:

Hitch assist

Hitch assist

Hitch assist switch

Hitch assist switch Enable and directional buttons

Enable and directional buttonsAuxiliary 3-point hitch control

The new auxiliary 3-point hitch control, on the left-hand fender, allows the operator to raise or lower the hitch while standing on the ground behind the tractor.

Pairing the auxiliary 3-point hitch control with hitch assist, changing implements has never been easier. Both features are in base equipment for 4R Series eHydro™ models.

Auxiliary 3-point hitch control (open station tractor)

Auxiliary 3-point hitch control (open station tractor) Auxiliary 3-point hitch control (cab tractor)

Auxiliary 3-point hitch control (cab tractor) iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch (LVB25976) iMatch Quick-Hitch with rotary cutter hookup (LVB25976)

iMatch Quick-Hitch with rotary cutter hookup (LVB25976)One of the greatest customer concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch.

The iMatch Quick-Hitch provides easy hookup and a guaranteed fit for all Category 1 implements that are designed to meet the ASAE Category 1 Standard S278.6 for quick-attach hitches.

NOTE: The bushing set can be seen in the picture above. These bushings allow the hooks on the iMatch and the pins on the implement to fit together properly. All other implements (box blades, tillers, rear blades, etc.) will require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the Parts system or through a bushing supplier (see dimensions below).

The optional field-installed 540/540 economy power take-off (PTO) allows operators to select the engine rpm needed for their PTO application. The economy position provides 540 rpm to the PTO at approximately 70 percent of the engine's normal rated speed. The engine runs at a rated speed of approximately 1750 rpm in the 540 economy position. The 540 economy is ideal for any PTO application, from running a mower to a baler or a cutter, where full horsepower is not needed. Operating at lower engine rpm decreases fuel costs during tasks. The overall operating experience improves because there is less noise and vibration for the operator.

A conveniently located lever (behind the seat of the tractor) allows the operator to simply change between 540 and 540E when conditions merit the opportunity to save fuel without affecting performance. For heavy-duty operations that require maximum PTO power, the PTO shift lever is placed in the 540 position, the PTO engaged, and the engine is run at rated speed of 2400 rpm. This selection gives 540 rpm to the PTO shaft and delivers the full-advertised horsepower at rated engine speed.

The 540/540 economy PTO offers all the features of the standard 540-rpm PTO, and the safety interlock

is a foolproof measure provided to compensate for operator oversight. When the tractor is in economy,

the engine is limited to a lower operating speed, preventing accidental over speeding of PTO implements

and protecting against binding the PTO shaft. The safety interlock also prevents accidental shifting of

the PTO selector lever at higher engine speeds than the economy PTO setting, which would lead to

downtime to fix implements or drivetrains.

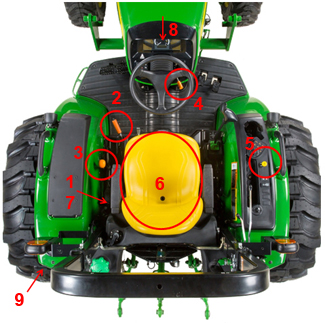

Regular service and maintenance are essential to the performance, productivity, and longevity of the tractor.

Removable side panels

Removable side panels Integrated grille maintenance position

Integrated grille maintenance position Removable cowl

Removable cowlAll items in the daily service schedule can be performed without the use of tools:

NOTE: Always refer to the operator’s manual for complete maintenance and service recommendations.

Compare the specifications of up to 4 models

| Key Specs | 4044r Current Model |

|---|---|

| Engine power (gross) | 31.7 kW 43.1 hp PS at 2600 rpm SAE J1995 rated power |

| Power take-off (PTO) power | PRT - 25 kW 33.6 hp eHST - 24.1 kW 32.3 hp Per SAE J1995 |

| Steering hydraulics | 23.5 L/min 6.2 gpm |

| Implement hydraulics | 42.3 L/min 11.2 gpm |

| Hitch type | Category 1 |

| Lift capacity, 24-in. behind link arms | 1135 kg 2500 lb |

| Standard transmission; forward/reverse | eHydro Transmission (eHST) |

| Cruise control | Standard |

| Approximate shipping weight (open-station; cab) | OOS - 1710 kg 3770 lb Cab - 2120 kg 4675 lb |

| Wheelbase | 185.5 cm 73 in. |

| Engine | |

| Family | EYDXL2.19NDA FYDXL2.19NDA GYDXL2.19NDA |

| Manufacturer | Yanmar |

| Engine model | 4TNV88C-MJT |

| Engine power (gross) | 31.7 kW 43.1 hp PS at 2600 rpm SAE J1995 rated power |

| Power take-off (PTO) power | PRT - 25 kW 33.6 hp eHST - 24.1 kW 32.3 hp SAE J1995 |

| Rated engine speed | 2600 rpm |

| Type | Diesel |

| Injection pump type | High pressure common rail direct injection |

| Aspiration | Natural |

| Emissions compliance | Final Tier 4 |

| Cylinders/displacement | 4 / 2.189 L 4 / 133.5 cu in. |

| Number of cylinders | Four |

| Cylinder liners | Cast-in-block |

| Bore and stroke | 88x90 mm 3.46x3.54 in. |

| Compression ratio | 19.1:1 |

| Lubrication | Pressurized |

| Cooling system | Liquid |

| Air cleaner | Dual element with electronic restriction indicator |

| Engine torque at rated speed | 116 Nm 85.6 lb-ft |

| Fuel tank capacity | Rollover protective structure (ROPS) - 56.9 L 15 U.S. gal. Cab - 52.2 L 13.8 U.S. gal. |

| Electrical | |

| Battery size | 770 CCA |

| Alternator (12-V) | 75 amp |

| Starter size | 2 kW 2.68 hp |

| Fuel system | |

| Type | High pressure common rail direct injection |

| Fuel consumption | |

| Transmission | |

| Standard transmission; forward/reverse | eHydro transmission (eHST) |

| Optional transmission; forward/reverse | 12/12 PowrReverser transmission (PRT) |

| Left-hand reverser | PRT only |

| Transmission gear ranges | PRT - 12F/12R eHydro - Infinitely-variable, 3 range |

| Final drive | Planetary |

| Brakes | Multi-plate wet disc |

| Steering | Hydrostatic power steering |

| Clutch, wet/dry | Wet |

| Clutch disk diameter wet clutch | 129 mm 5.08 in. |

| Axle capacity | Front 1600 kg 3528 lb Rear 2400 kg 5292 lb |

| Creeper | SpeedMatch standard |

| Cruise control | Standard |

| Differential lock | Yes |

| Drawbar maximum vertical load | |

| Hydraulics | |

| Type | Open center |

| Pump rated output | Steering 23.5 L/min 6.2 gpm Implement 42.3 L/min 11.2 gpm 65.8 L/min 17.4 gpm |

| Pump type | Single gear |

| Maximum operating pressure | |

| Draft control sensing | Position control |

| Remote control valves available | Up to six rear remotes |

| 3-point hitch | |

| Type | Category 1 |

| Lift capacity, 24-in. behind link arms | 1135 kg 2500 lb |

| Power take-off (PTO) | |

| Standard | Independent 540 rpm at 2600 rpm |

| Optional | 540E rpm |

| Control | Position |

| Clutch | Wet disc |

| Brake (for mid and rear PTO) | |

| Engagement method | |

| Fluid capacities | |

| Crankcase with filter | 5.3 L 1.4 qt |

| Transmission and hydraulic system | 47.3 L 12.5 gal. |

| Final drive | |

| Type | Planetary |

| Differential lock | Yes |

| Operator station | |

| Rollover protective structure | Type Foldable Yes |

| Platform - flat/straddle | Flat |

| Gear shift location - console/floor | PRT - Left-hand side |

| Cab | |

| Compliance | OSHA, SAE, ASAE |

| Visibility | 360 degree (angle) |

| Air conditioning, temperature differential | 14.4 °C 58 °F |

| Doors | Two |

| Noise rating | 78 dBA |

| Seat equipment | Air suspension with swivel |

| Dimensions | |

| Wheelbase | 185.5 cm 73 in. |

| Front axle clearance | 35.1 cm 13.8 in. |

| Turning radius with brakes | 2.8 m 9.17 ft |

| Turning radius without brakes | 3 m 9.84 ft |

| Limited slip differential | |

| Approximate shipping weight (open-station; cab) | OOS - 1710 kg 3770 lb Cab - 2120 kg 4675 lb |

| Tires | |

| Front | Farm - 8-16 Turf - 27x10.5-15 or 27x12LL-15 Industrial - 10-16.5 |

| Rear | Farm - 13.6-28 Turf - 44x18-20 or 22.5LL-16.1 Industrial - 16.9Lx24 |

| Front tread range | 148.1 cm 58.3 in. |

| Rear tread spacing | 137.2 cm 54 in. |

| Miscellaneous | |

| Toolbox | |

| Tilt steering wheel | |

| 12-V Outlet |

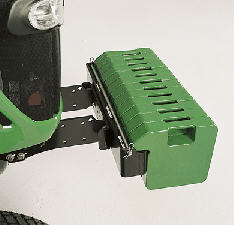

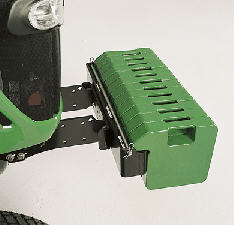

Ballast box shown with extension

Ballast box shown with extensionThe ballast box can be used to carry additional ballast for greater tractor stability.

A 9-in. high extension can be added to ballast box for even greater capacity.

A bushing kit is required for the ballast box to be used with the iMatch™ Quick Hitch.

BW14701 ballast box shown with BW15074 extension

BW14701 ballast box shown with BW15074 extension WP16011033 large ballast box

WP16011033 large ballast boxBallast boxes can be used to carry additional ballast for greater tractor stability.

NOTES:

1. Ballast box BW14701 has Category 1 pins and is compatible with a Category 1, 3-point hitch. It can be made Category 1 quick-hitch (iMatch™ hitch) compatible by adding BW15056 bushing kit.

2. The large ballast box (WP16011033) has Category 2 pins and is compatible with a Category 2, 3-point hitch. The large ballast box (WP16011033) is not quick-hitch-compatible.

3. Requires (2) R66432 bushing, (1) M115827 quick-lock pin, (1) R58262 pin, and (1) T12553 bushing to convert Category 1 ballast box to Category 2.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mountRAM is a trademark of National Products Inc.

Air-ride suspension kit

Air-ride suspension kitThe air-ride seat suspension provides vertical and horizontal seat suspension for maximum operator comfort in any terrain.

Key benefits include:

This kit includes air-ride seat suspension, adapter plate, close-out boot, and push pins. The cab is pre-wired for this kit. The kit does not include an actual seat, but rather the suspension kit replaces the mechanical standard suspension on the existing seat.

For cab tractors only.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mountRAM is a trademark of National Products Inc.

Rear wiper kit

Rear wiper kitThe rear wiper kit provides better rear visibility during inclement weather. It includes a wiper and a wiper nozzle that disperses fluid to clean the window.

A favorite worldwide, the RAM self-leveling cup holder is now available as a kit - designed specifically for Deere equipment. It is easily installed to keep your favorite beverage upright even in the roughest terrain. The perfect accessory for any cab that has 10-mm mounting bosses.

Self-leveling cup holder John Deere branded beverage insulator included

Self-leveling cup holder John Deere branded beverage insulator included

The new cup holder features a unique self-leveling design. This pivoting design allows easy adjustment for the holder while offsetting motion of the vehicle when moving.

Features and applications:

Magnetic hitch pin

Magnetic hitch pinFits John Deere lawn and garden tow behind attachments.

Customers, please contact your local John Deere dealer for availability and pricing information.

Magnetic hitch pin

Order number: LP63768

Engine coolant heater kit

Engine coolant heater kitAttached to the engine cylinder block, the engine coolant heater plugs into a 120-V electrical outlet to warm the engine for fast cold-weather starts.

NOTE: It is recommended to install optional engine coolant heater, transmission oil heater, and battery heating pad (A22400P - ordered through A and I) if operating machine in temperatures below -18 ⁰C (0⁰F).

An optional, newly designed front 3-point hitch is available for quick hookup of 3-point hitch front implements (non PTO driven implements).

The new front hitch option meets Category 1 hitch specifications and allows easy connect and disconnect of front implements. This helps to ensure reduced setup time and maximum productivity.

The heavy-duty designed front hitch integrates perfectly into the 4R Tractor frame and makes this front hitch the perfect choice for those customers looking for maximum performance and productivity when using front implements.

The variety of options does allow tailoring the perfect configuration.

An optional, newly designed front 3-point hitch is available for quick hookup of 3-point hitch front implements (non PTO driven implements).

The new front hitch option meets Category 1 hitch specifications and allows easy connect and disconnect of front implements. This helps to ensure reduced setup time and maximum productivity.

The heavy-duty designed front hitch integrates perfectly into the 4R Tractor frame and makes this front hitch the perfect choice for those customers looking for maximum performance and productivity when using front implements.

The variety of options does allow tailoring the perfect configuration.

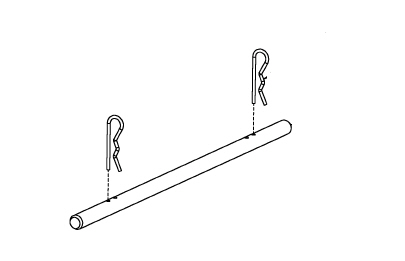

Weight kit

Weight kitRod and pins that allow weights to be bolted together to remain on tractor.

Weight bracket extension installed on a 3120

Weight bracket extension installed on a 3120Can be attached to tractor to allow using up to 12 front weights. Extension kit includes extension bracket, hardware, rod, and pins.

Order weights separately.

Allow 30 minutes to install.

NOTE: Front weights and front hitch are not compatible on same tractor.

Weight bracket extension installed on a 3120

Weight bracket extension installed on a 3120Can be attached to tractor to allow using up to 12 front weights. Extension kit includes extension bracket, hardware, rod, and pins.

Order weights separately.

Allow 30 minutes to install.

NOTE: Front weights and front hitch are not compatible on same tractor.

Dual mid-SCV

Dual mid-SCV

The tractor is base equipped with a dual mid-selective control valve (DSCV).

Up to three additional SCVs can be added, totaling five:

EH third SCV

EH third SCV Fourth and fifth SCV

Fourth and fifth SCV 6-way diverter valve

6-way diverter valveEH third SCV kit

Fourth and fifth rear SCV kit (dual rear SCV)

6-way diverter valve kit

Optional on the 4R Series Tractors, the diverter valve kit:

Electric diverter switch (cab tractor)

Electric diverter switch (cab tractor)Once the diverter switch is engaged, the loader joystick can be used to activate three rear hydraulic outlets. A combination of the loader joystick and thumb control will provide effortless control of the rear hydraulics.

Power beyond kit

Power beyond kit

Optional on the 4R Series Tractors, the power beyond kit:

Hydraulic configuration compatibility matrix

Dual rear SCV | EH third SCV | Power beyond | 6-way diverter | Top and tilt | |

Dual rear SCV |

| Y | Y | Y | Y |

EH third SCV | Y |

| Y | Y | Y |

Power beyond | Y | Y |

| Y | Y |

6-way diverter | Y | Y | Y |

| Y |

Top and tilt | Y | Y | Y | Y |

|

Downforce | Y | Y | Y | N | N |

SCV controls

SCV controls

NOTE: REGEN hydraulics should never been hooked to a motor or to a 2-cylinder angling operation such as a snowblade.

Dual mid-SCV

Dual mid-SCV

The tractor is base equipped with a dual mid-selective control valve (DSCV).

Up to three additional SCVs can be added, totaling five:

EH third SCV

EH third SCV Fourth and fifth SCV

Fourth and fifth SCV 6-way diverter valve

6-way diverter valveEH third SCV kit

Fourth and fifth rear SCV kit (dual rear SCV)

6-way diverter valve kit

Optional on the 4R Series Tractors, the diverter valve kit:

Electric diverter switch (cab tractor)

Electric diverter switch (cab tractor)Once the diverter switch is engaged, the loader joystick can be used to activate three rear hydraulic outlets. A combination of the loader joystick and thumb control will provide effortless control of the rear hydraulics.

Power beyond kit

Power beyond kit

Optional on the 4R Series Tractors, the power beyond kit:

Hydraulic configuration compatibility matrix

Dual rear SCV | EH third SCV | Power beyond | 6-way diverter | Top and tilt | |

Dual rear SCV |

| Y | Y | Y | Y |

EH third SCV | Y |

| Y | Y | Y |

Power beyond | Y | Y |

| Y | Y |

6-way diverter | Y | Y | Y |

| Y |

Top and tilt | Y | Y | Y | Y |

|

Downforce | Y | Y | Y | N | N |

SCV controls

SCV controls

NOTE: REGEN hydraulics should never been hooked to a motor or to a 2-cylinder angling operation such as a snowblade.

Dual mid-SCV

Dual mid-SCV

The tractor is base equipped with a dual mid-selective control valve (DSCV).

Up to three additional SCVs can be added, totaling five:

EH third SCV

EH third SCV Fourth and fifth SCV

Fourth and fifth SCV 6-way diverter valve

6-way diverter valveEH third SCV kit

Fourth and fifth rear SCV kit (dual rear SCV)

6-way diverter valve kit

Optional on the 4R Series Tractors, the diverter valve kit:

Electric diverter switch (cab tractor)

Electric diverter switch (cab tractor)Once the diverter switch is engaged, the loader joystick can be used to activate three rear hydraulic outlets. A combination of the loader joystick and thumb control will provide effortless control of the rear hydraulics.

Power beyond kit

Power beyond kit

Optional on the 4R Series Tractors, the power beyond kit:

Hydraulic configuration compatibility matrix

Dual rear SCV | EH third SCV | Power beyond | 6-way diverter | Top and tilt | |

Dual rear SCV |

| Y | Y | Y | Y |

EH third SCV | Y |

| Y | Y | Y |

Power beyond | Y | Y |

| Y | Y |

6-way diverter | Y | Y | Y |

| Y |

Top and tilt | Y | Y | Y | Y |

|

Downforce | Y | Y | Y | N | N |

SCV controls

SCV controls

NOTE: REGEN hydraulics should never been hooked to a motor or to a 2-cylinder angling operation such as a snowblade.

Dual mid-SCV

Dual mid-SCV

The tractor is base equipped with a dual mid-selective control valve (DSCV).

Up to three additional SCVs can be added, totaling five:

EH third SCV

EH third SCV Fourth and fifth SCV

Fourth and fifth SCV 6-way diverter valve

6-way diverter valveEH third SCV kit

Fourth and fifth rear SCV kit (dual rear SCV)

6-way diverter valve kit

Optional on the 4R Series Tractors, the diverter valve kit:

Electric diverter switch (cab tractor)

Electric diverter switch (cab tractor)Once the diverter switch is engaged, the loader joystick can be used to activate three rear hydraulic outlets. A combination of the loader joystick and thumb control will provide effortless control of the rear hydraulics.

Power beyond kit

Power beyond kit

Optional on the 4R Series Tractors, the power beyond kit:

Hydraulic configuration compatibility matrix

Dual rear SCV | EH third SCV | Power beyond | 6-way diverter | Top and tilt | |

Dual rear SCV |

| Y | Y | Y | Y |

EH third SCV | Y |

| Y | Y | Y |

Power beyond | Y | Y |

| Y | Y |

6-way diverter | Y | Y | Y |

| Y |

Top and tilt | Y | Y | Y | Y |

|

Downforce | Y | Y | Y | N | N |

SCV controls

SCV controls

NOTE: REGEN hydraulics should never been hooked to a motor or to a 2-cylinder angling operation such as a snowblade.

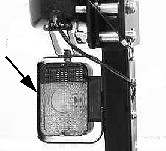

Rear work light

Rear work lightThis kit provides light to the rear of the tractor for evening work.

For open-station tractors only, this kit contains individual light.

Allow 30 minutes to install.

NOTE: Kit includes one rear light.

NOTE: Both the rear- and forward-work lights are compatible together and with the light-brush guard kits. The light kit contains a two-to-four pigtail that plugs into the main harness, as if only plugging one set of lights, providing two sets of plugs to use for forward and rear-work lights. The forward light is installed on top of the brush guard, and the rear light is installed inside the ROPS using the bolt holding the light and brush guard on.

NOTE: For 102E3 and 1026R Tractors – kit interference during backhoe operations (mounted inside ROPS) – use LVB25546 forward-light kit as an alternative.

The forward-lighting kit provides extra visibility when working in dark conditions. Lights attach to the brush guards located on the rollover protective structure (ROPS). Each kit contains two lights.

NOTE: Requires BLV10400 warning light brush guard kit and LVB26026 light kit harness. Not compatible with LVB25547 rear work light kit (1023E).

NOTE: Requires BLV10400 warning light brush guard kit. Not compatible with LVB25547 rear work light kit (1025R, 2025R, 2032R, 2038R, 3025E, 3032E, 3038E, 4105, 4044M, 4052M, 4066M).

NOTE: Requires BLV10620 premium warning light brush guard kit. Not compatible with LVB25547 rear work light kit (3033R, 3039R, 3046R, 4044R, 4052R, 4066R).

Rollover protective structure (ROPS) mounted LED work lights

An optional LED work light kit is available for all open-station compact utility tractors. These lights provide extra visibility when working in dark conditions and have 180-degree rotation to face forward or backward. The kit contains two lights and the mounting hardware required for installation.

This lighting kit is mounted to the warning light brush guard kit, which is mounted to the ROPS and requires attachment BLV10400 for installation.

The halogen work light kit attachment is still available (LVB25546).

Shown on 4000 TEN Series Tractor

Shown on 4000 TEN Series TractorROPS warning-light brush guards protect turn signal/warning lights from damage caused by low branches on trees.

For open-station tractors only.

Two guards included in each kit.

An optional premium light kit is available to provide extra visibility when working in dark conditions. The premium light kit includes the following:

The beacon light may be required for certain governmental or commercial applications. This kit consists of a rotating, high-intensity light that rests inside an amber-colored safety lens. A rocker switch controls its actuation. It can be located on the right-hand control panel for convenient access.

The top of the beacon light is 8 in. above the cab roof.

Allow 30 minutes for installation.

Rear work light kit

Rear work light kitAllow 30 minutes to install.

External mirror kit

External mirror kitDual external mirrors provide a wide rear view of road or field and can be ordered for use on cab models. This kit contains one left-side and one right-side mirror with mounting hardware.

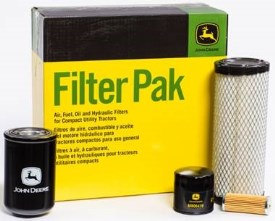

Typical home maintenance kit

Typical home maintenance kitFilter Paks are a handy and convenient way for dealers to supply a customer with the maintenance-interval parts as specified in their operator's manual. These kits contain an oil filter, air filter, fuel filter and hydraulic filter, offering a complete solution for all your customers’ maintenance needs to keep their tractors running at peak performance.

Benefits of Filter Paks:

Easy to understand – indicates models and contents so you never have to worry about the right filters for your compact utility tractor

A horn provides audible alert to bystanders.

Allow 20 minutes to install.

The air-ride seat suspension provides vertical and horizontal seat suspension for maximum operator comfort in any terrain. Key benefits include:

This kit includes air-ride seat suspension, adapter plate, close-out boot and push pins, and wiring harness. The kit does not include an actual seat, but rather the suspension kit replaces the mechanical standard suspension on the existing seat.

For open-station tractors only.

Canopy

CanopyThe canopy attaches to the rollover protective structure (ROPS) to protect the operator from inclement weather.

NOTE: Additional mounting brackets are required to adapt the canopy (LVB25334) to ROPS. See ordering information below.

Canopy mounting kit

Canopy mounting kitThe canopy attaches to the rollover protective structure (ROPS) to protect the operator from inclement weather.

For open-station tractors only.

NOTE: Additional mounting brackets are required to adapt the canopy (LVB25334) to ROPS. See ordering information below.

Umbrella

UmbrellaProvides the operator the necessary shade and protection from the elements.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mountRAM is a trademark of National Products Inc.

Optional rear extension fenders and front turnable fenders are now available for 3R and 4R Cab Tractors. These fender options provide tire coverage to protect the cab from mud and debris.

Rear wheel weight, 110 lb

Rear wheel weight, 110 lb iMatch Quick-Hitch (LVB25255)

iMatch Quick-Hitch (LVB25255) iMatch Quick-Hitch with rotary cutter hookup (LVB25255)

iMatch Quick-Hitch with rotary cutter hookup (LVB25255) iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch (LVB25976) iMatch Quick-Hitch with rotary cutter hookup (LVB25976)

iMatch Quick-Hitch with rotary cutter hookup (LVB25976)One of the greatest customer concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch.

The iMatch Quick-Hitch provides easy hookup and a guaranteed fit for all Category 1 implements that are designed to meet the ASAE Category 1 Standard S278.6 for quick-attach hitches.

NOTE: In the picture above, you see the bushing set. These bushings allow the hooks on the iMatch and the pins on the implement to fit together properly. All other implements (box blades, tillers, rear blades, etc.) will require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier (see dimensions below).

© COPYRIGHT 2025 LEGACY EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By