February Parts Special - Order Through Shop.Deere.Com

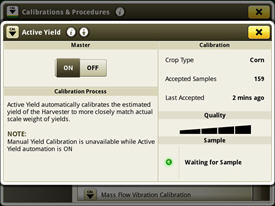

ActiveYield delivers automatic yield calibrations to the operator without spending time manually performing yield calibrations.

Feature benefit:

Functionality:

ActiveYield eliminates time-consuming manual yield calibrations and replaces them with automated sensors that calibrate the machine by measuring the grain as the tank fills. This enables decisions to be made in real time without leaving the cab.

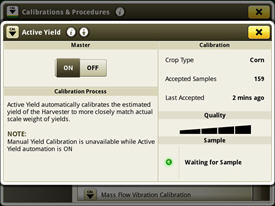

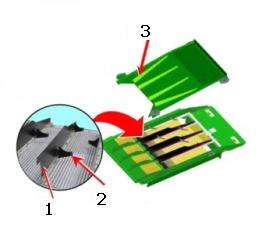

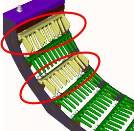

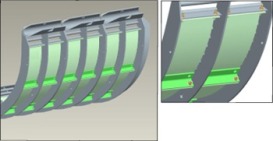

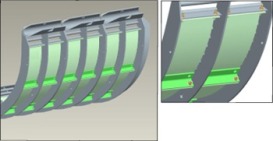

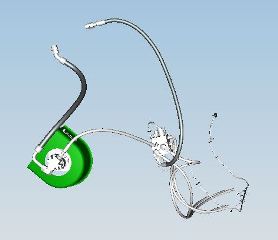

ActiveYield sensors in grain tank

ActiveYield sensors in grain tankWhen the ActiveYield option is enabled and the Terrain Compensation Module (TCM) in the StarFire™ 3000 or StarFire 6000 Receiver has been calibrated, ActiveYield is ready to go to work. As grain is harvested and enters the tank, the three sensors within the grain tank collectively measure the grain as it piles over the cross auger covers. If all conditions are acceptable (header and separator on, grain is flowing, and machine level is within 4 degrees) load collection occurs from 900 through 3000 kg (2000 through 6600 lb).

Any pitch and roll of more than 4 degrees from center during load collection will cause the system to reject that load due to the grain pile shifting in the tank. A new calibration load starts once grain is below the sensors on the cross auger covers.

Stored calibration loads are replaced by new ones as the system continues to collect data. The system may be disabled at any time by accessing the moisture setup page and unchecking the ActiveYield box if manual yield calibration is desired.

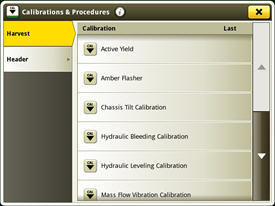

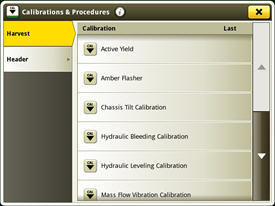

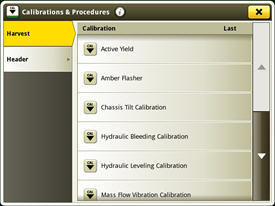

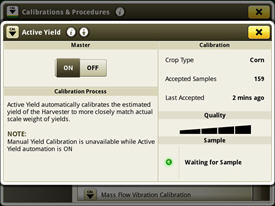

ActiveYield calibration location

ActiveYield calibration location ActiveYield Information

ActiveYield InformationActiveYield is available for model year 2016 through model year 2019 S760, S770, S780, and S790 Combines and requires the 4600 CommandCenter™ Display, GreenStar™ 3 2630 Display, or GreenStar 3 CommandCenter. Additionally, a StarFire 3000 or 6000 Receiver must be installed on the combine with the TCM calibrated for ActiveYield to detect machine pitch correctly. Manual yield calibration is not required as each crop has a built-in default value.

Harvest Doc™ system yield data collected by an ActiveYield system is only compatible with the John Deere Operations Center. John Deere does not guarantee compatibility of ActiveYield collected documentation with John Deere APEX™ software or third-party software systems.

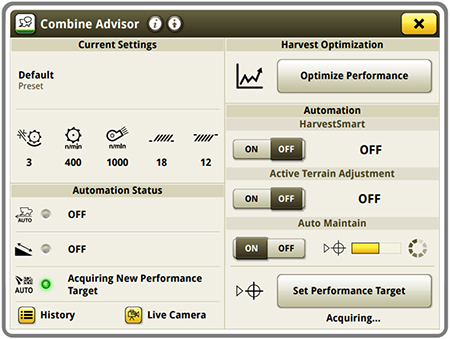

Combine Advisor is a suite of technologies designed to maximize harvesting profits. The features help the operator set and optimize the S700 Combine and then automates the combine to maintain performance target as conditions change. Purchasing Combine Advisor grants access to the Combine Advisor application, which houses three automation technologies: HarvestSmart™ system for automation of feed rate, Active Terrain Adjustment™ system for terrain change management, and Auto Maintain with ActiveVision™ cameras for crop condition change management.

Combine Advisor also provides easy navigation of the S700 set and optimize features: harvest settings application for initial set up and setting storage, VisionTrak system for monitoring losses, and Optimize Performance for step-by-step guidance of combine setting optimization. Once John Deere Combine Advisor is set into motion, the operator will experience ease-of-use benefits coupled with increased productivity.

Code | Description |

1962

| Combine Advisor Base features, plus Active Terrain Adjustment and Combine Advisor. Includes ActiveVision cameras.

Base features include Optimize Performance, TouchSet™ system, VisionTrak, HarvestSmart, and engine speed management. HarvestSmart and engine speed management only included with code 2020 (ProDrive™ transmission). Engine speed management only available with Final Tier 4 (FT4) engines. |

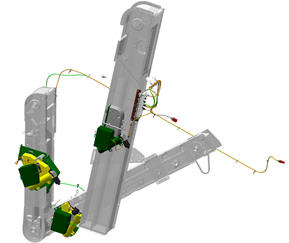

Combine Advisor bundles are available for model year 2018 and future models. The bundles include ActiveVision cameras, harnesses, Auto Maintain, and software.

Dealer installation instructions are included, as weldments and drilling are required. The process will most likely take around 10 hours of labor.

| Bundle | Description |

BXE11034 | Combine Advisor retrofit bundle for S760 and S770 Combines Also requires BXE10948 Active Terrain Adjustment bundle if the combine is not already equipped with code 1961 (base features + Active Terrain Adjustment) |

| BXE11035 | Combine Advisor retrofit bundle for S780 and S790 Combines Also requires BXE10948 Active Terrain Adjustment bundle if the combine is not already equipped with code 1961 (base features + Active Terrain Adjustment) |

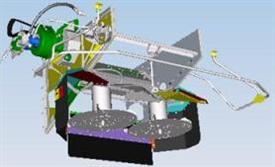

Combine Advisor retrofit bundle components

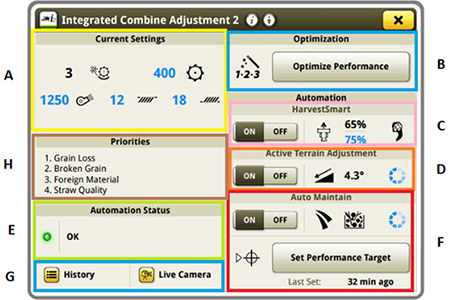

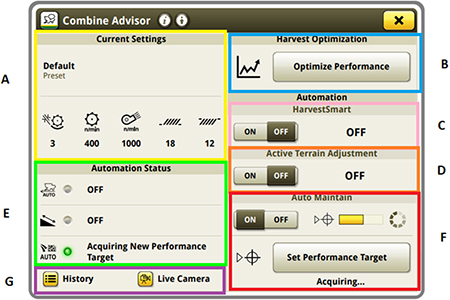

Combine Advisor retrofit bundle components ICA2 run page, model years 2018 and 2019

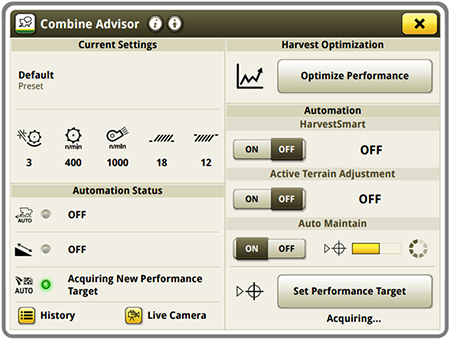

ICA2 run page, model years 2018 and 2019 Combine Advisor run page changes beginning with model year 2020

Combine Advisor run page changes beginning with model year 2020| ICA2 run page, model year 2018 | Combine Advisor run page, model year 2020 |

| Section A (yellow highlight): takes the operator to the current settings for concave clearance, rotor speed, fan speed, chaffer clearance, and sieve clearance, giving quick access to critical combine adjustments. | Section A (yellow highlight): takes the operator to the current settings for concave clearance, rotor speed, fan speed, chaffer clearance, and sieve clearance, giving quick access to critical combine adjustments. It also shows the currently selected preset. |

| Section B (blue highlight): the Optimize Performance button helps the operator optimize combine performance. | Section B (blue highlight): the Optimize Performance button helps the operator optimize combine performance. |

| Section C (pink highlight): the HarvestSmart system automates ground speed control during harvest to maintain a constant crop load. | Section C (pink highlight): the HarvestSmart system automates ground speed control during harvest to maintain a constant engine load. The Manage Target with Grain Loss setting enables an automatic target adjustment based on loss levels. |

| Section D (orange highlight): the Active Terrain Adjustment system produces better grain quality and fewer losses while controlling tailings volume when harvesting up and down hills. | Section D (orange highlight): the Active Terrain Adjustment system produces better grain quality and fewer losses while controlling tailings volume when harvesting up and down hills. |

| Section E (green highlight): automation status | Section E (green highlight): Combine Advisor system – HarvestSmart, Active Terrain Adjustment, and Auto Maintain. |

| Section F (red highlight): Auto Maintain monitors the combine and makes adjustments to maintain the performance at the operator-set performance target. | Section F (red highlight): Auto Maintain monitors the combine and makes adjustments to maintain the performance at the operator-set performance target. |

| Section G (purple highlight): Auto Maintain also uses the buttons in section G to allow a glimpse into live views of the clean grain and tailings elevators and allows operators to use an analyzer function to see what Auto Maintain is seeing. It also shows a list of adjustments made by Auto Maintain and Active Terrain Adjustment. **In sections C, D and F select the screen area to see additional sensitivity settings for each system. | Section G (purple highlight): Auto Maintain also uses the buttons in section G to allow a glimpse into live views of the clean grain and tailings elevators and allows operators to use an analyzer function to see what Auto Maintain is seeing. It also shows a list of adjustments made by Auto Maintain and Active Terrain Adjustment. **In sections C, D and E select the screen area to see additional sensitivity settings for each system. |

| Section H (brown highlight): indicates the operator’s priorities for automation | --- |

|

|

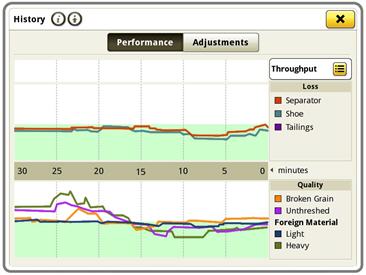

Historical Auto Maintain performance graph

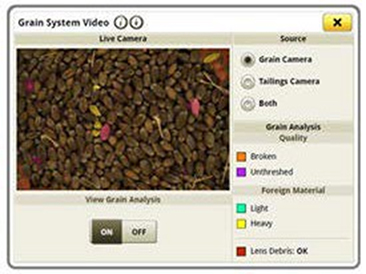

Historical Auto Maintain performance graphThe ActiveVision cameras can detect broken and unthreshed grain. The cameras will also detect lightweight and heavy foreign material to make the appropriate combine settings changes. The system provides a live feed of both the grain and tailings cameras and will highlight the parameters outlined to make it easier to analyze. The live view and historical graphs update constantly, and the cameras will even tell the operator if there is debris on the lens.

Grain analysis live view

Grain analysis live view | Combine Advisor with Auto Maintain is available as a factory-installed option on combines since model year 2018. Auto Maintain is compatible in corn, soybeans, wheat, canola, and barley. Retrofit kits, BXE11034 and BXE11035 are available. Please refer to that section for more information. |

Combine Advisor run page

Combine Advisor run pageThe Combine Advisor application provides the tools needed to set the combine to get the most out of it and automatically adjust settings to maintain optimum performance. Inside this application on the 4600 CommandCenter™ Display, the operator will find many tools including easy-to-adjust current machine settings, sensitivity settings for automation, application status indicators, automation activity history overviews, and live feeds of grain analysis cameras.

Additionally, the operator can access Optimize Performance, activate the three automation technologies, and set the performance targets the machine will automatically adjust to maintain.

Feature benefits:

Functionality:

Auto Maintain with ActiveVision cameras is technology that works to automatically adjust five primary S700 Combine settings to maintain the user set performance target. When harvesting corn, soybeans, wheat, canola, or barley, the combine will maintain the performance of everything from grain loss and grain quality, to foreign material in the grain tank. The ActiveVision cameras, along with grain loss monitors, are specifically designed to identify the impact of crop condition changes and adjust the combine to maintain the performance target, allowing the operator to focus on other challenges of harvest.

Feature benefits:

Simplify harvest by automating the critical workload of constantly managing combine settings when conditions change

Increase productivity by allowing ActiveVision cameras to identify and address tough-to-spot problems such as cracked grain

Provide flexibility in planning overall business and increase the efficiency of the combine independent of operator experience

Combine Advisor run page

Combine Advisor run pageFunctionality

Auto Maintain looks at the level at which the combine is performing, sets that as the goal, and automates combine settings to continually hit the target performance goal over time. Auto Maintain uses existing sensor inputs along with the ActiveVision cameras to make decisions for accurate combine adjustments. It does not use grain moisture as an input, however. Auto Maintain is able to hit the target goal by automatically making adjustments to the threshing speed, concave clearance, chaffer clearance, sieve clearance, and fan speed. The ActiveVision cameras have been trained to analyze the clean grain and tailings material and input that analysis into the Auto Maintain system. Auto Maintain will show the operator how it has been performing with a constantly updating historical graph of losses, grain quality, and foreign material in the clean grain. The green-shaded area below indicates the performance targets set. The colored lines show the ongoing levels of losses and quality. For example, the green, purple, and orange lines below show a period of time outside of the green-shaded acceptable area. Auto Maintain recognizes this and makes the appropriate adjustments to meet the set targets.

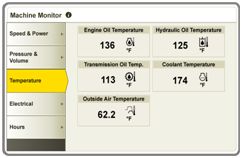

The Generation 4 CommandCenter was designed to provide a consistent user experience by providing full-screen viewing of more run page modules, shortcut keys, and precision agriculture capabilities.

Expect easier set-up, along with increased operator confidence, thanks to a simple, customizable interface. The improved design of the Generation 4 CommandCenter also aids in an optimal operating experience and maximizes uptime.

In order to increase your efficiency, take advantage of the following features offered by the Generation 4 CommandCenter:

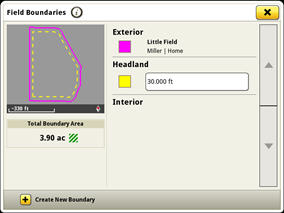

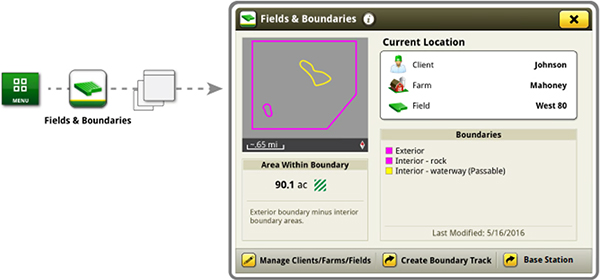

Layout manager selection page

Layout manager selection page Layout manager module build

Layout manager module build Machine monitor page

Machine monitor page Work monitor page

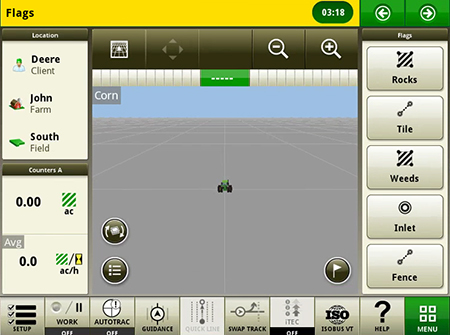

Work monitor page Create flags to mark items in the field

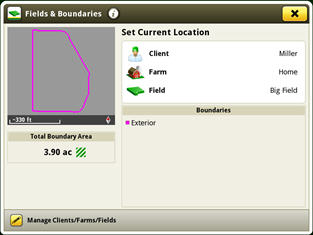

Create flags to mark items in the field Boundary creation from coverage

Boundary creation from coverage Headland creation

Headland creation Dual display

Dual displayNOTE: Vehicle applications will always be located on the Gen 4 CommandCenter.

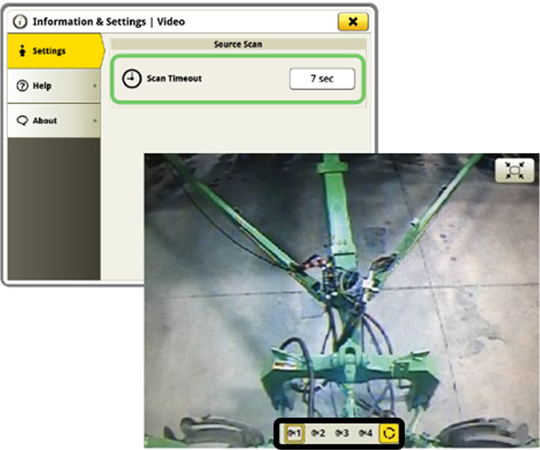

Setup base stations in Fields and Boundaries applications

Setup base stations in Fields and Boundaries applications Scan through videos with video looping

Scan through videos with video looping

Harvest is hectic. Producers are focusing on getting all the crop from the field to the bin within a tight harvest window. Using Machine Sync, those producers can focus more on grain harvest and grain quality, and worry less about keeping the grain cart under the spout when unloading on the go. Gen 4 Machine Sync provides a solution to harvest stress by creating a wireless network between the tractor and combine to enable on-the-go unloading by synchronizing tractor speed and direction of travel with the combine.

Machine Sync works with In-Field Data Sharing to show the location of all combines and tractors within the fleet of Gen 4 machines harvesting in the field. Knowing the exact location of multiple combines as well as their grain tank fill level and unloading auger status allows the grain cart operators to be in the right place at the right time.

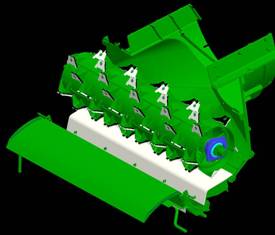

The Dyna-Flo Plus cleaning shoe is the heart of the S700 Combine cleaning system. The system is made up of a unique design consisting of aluminum and high-strength steel that reduces overall weight while maintaining overall strength. The Dyna-Flo Plus cleaning shoe also features an enhanced drive system that requires only one flywheel for optimal shoe performance and maximizes uptime.

Feature benefit:

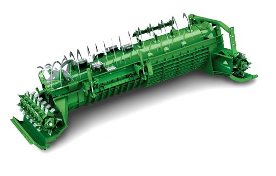

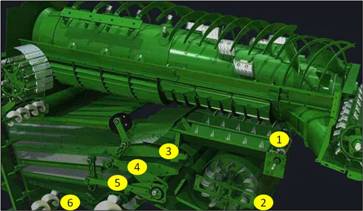

Dyna-Flo Plus cleaning shoe

Dyna-Flo Plus cleaning shoe Enhanced drive system

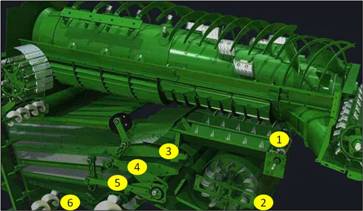

Enhanced drive systemThe Dyna-Flo Plus cleaning system begins with conveyor augers located beneath the concave area, where the volume of threshed material is highest, to evenly move material onto the cleaning shoe (1). The deep auger troughs provide uniform distribution of material to the cleaning shoe with less bunching, even on sloping terrain and when harvesting up and down hills.

Dyna-Flo Plus cleaning shoe

Dyna-Flo Plus cleaning shoeOnce grain is on the cleaning shoe, the raised-center front chaffer cleans up to 40 percent of free grain before it reaches the main chaffer (3). High-velocity air from the cleaning fan elevates any light material traveling over the end of the front chaffer, resulting in more aggressive separation of chaff and increased cleaning performance (2). The main chaffer provides grain separation from chaff as the grain passes through the main chaffer to the sieve (4).

The sieve provides proper sizing of grain from material other than grain (5). Any grain that passes through the sieve is elevated to the grain tank while some grain or material other than grain flows to the tailings return system for reprocessing. On S760, and S770 Combines, the tailings material is directed back into the threshing section of the separator for additional threshing. The tailings material on the S780 and S790 Combines are directed to the active tailings return system for additional threshing, and then directed back on the return pan and then onto the main chaffer for additional cleaning (6).

Harvesting in slopes

Harvesting in slopes Harvesting in rolling ground

Harvesting in rolling groundThe industry-exclusive ProDrive system uses PowerShift™ transmission technology to automatically shift between two speed ranges as ground conditions and terrain change to keep the combine harvesting at the desired ground speed. Valuable harvest time will no longer be lost shifting on hills and when exiting fields to start transporting.

Feature benefit:

The ProDrive system on S700 Combines includes an integrated HarvestSmart™ feedrate control system to provide the maximum productivity and reduce operator stress and fatigue.

Functionality:

The ProDrive hydrostatic motor has a higher displacement than the previous hydrostatic systems. Both the pump and motor are variable-displacement components that allow ProDrive to maintain high levels of torque to the ground throughout each of the two operating-speed ranges.

Range one can be set for typical harvesting speeds. Range two can be used when higher speeds are needed during harvest or when transporting the combine.

The ground speed can be infinitely varied within both modes by the operator, using the multifunction control lever on the CommandARM™ armrest console. The multifunction lever regulates the high-capacity, variable hydrostatic pump and motor that drives the ground speed.

Using the navigation tools on the armrest, the operator can dial in the desired maximum-attainable speed within each of the two speed ranges. The maximum forward speed in either range can be set from 0 to 38.6 km/h (0 to 24 mph). The maximum speed in range one cannot be set higher than the maximum speed for range two. For example, if a maximum harvest speed of 13 km/h (8 mph) is desired and set, the full forward position of the hydrostatic control handle will deliver the speed of 13 km/h (8 mph).

The ProDrive transmission is equipped with an electrohydraulic differential lock with a four-pinion differential. Non-ProDrive combines have a two-pinion differential. When operating in muddy, hilly terrain or in sandy conditions that may cause one of the tires to lose traction, this differential lock enables the operator to maintain productivity. If traction is lost, the operator can quickly and easily engage the differential lock by pressing the differential lock button on the CommandARM armrest console. An indicator light within the button alerts the operator that the differential locking feature is engaged.

Platform tilt allows operators to hydraulically adjust the fore-aft pitch of front-end equipment at the touch of a button from inside the cab to adapt to changing crop and field conditions.

Hydraulic fore-aft feederhouse

Hydraulic fore-aft feederhouse Hydraulic fore-aft multifunction control lever

Hydraulic fore-aft multifunction control leverThe platform tilt feature includes a different multifunction lever (hydro handle) to adjust the feederhouse tilt frame from the cab.

All S700 Combines provide an optional hydraulic header fore-aft tilt capability from the cab. However, all S700 Combines include a front-tilting faceplate as standard equipment. This tilting faceplate allows static fore-aft adjustment of up to 17 degrees of tilt on the feederhouse to accommodate different header and tire combinations to ensure a parallel cutterbar-to-ground relationship. This prevents the cutterbar knife guards from bulldozing or the platform healing on the rear of the skid shoes.

NOTE: Hydraulic fore-aft adjustment range is limited based upon the front-end equipment attached to prevent header frame damage. Check availability in local Price Pages.

The TriStream rotor is unique to John Deere because it features a slightly tapered design in the threshing area for best-in-class grain quality while dramatically reducing the growling that often comes with heavy rotor loads. The TriStream rotor is recommended for producers who harvest mainly coarse grains along with easy-threshing small grains.

The spiral vanes surrounding the rotor guide the crop material through the threshing and separating area in a pull-and-release action to improve performance. This John Deere S700 Combine feature will generate less power consumption.

Feature benefits:

S700 TriStream rotor

S700 TriStream rotorFunctionality:

Fifteen cast-constructed threshing elements provide superior material handling with excellent grain quality. The elements spiral around the rotor to control material flow. In some harvesting environments, the dense-pack configuration (nine additional threshing elements) may be necessary.

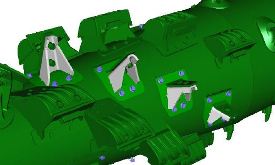

TriStream threshing elements

TriStream threshing elementsConical top covers allow for smooth material movement within the threshing and separating area. The top covers have a radius larger than the rotor, allowing the material to expand as it travels along the top of the rotor. This design uses the pull-and-release action of crop material, aiding in the threshing and separating to reduce power consumption.

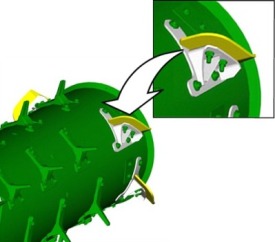

Conical top covers

Conical top coversThe industry-exclusive variable-stream rotor features a tapered design in the threshing section, which improves crop flow, enhances grain quality, and reduces power consumption. The variable-stream rotor with adjustable top cover transport vanes is recommended for producers of rice and in tough threshing conditions.

The variable-stream rotor smooths crop flow during tough handling conditions to maximize throughput. Along with the tough-material handling capabilities of the variable-stream rotor configuration, the straw quality and length can be improved due to the electrically adjustable top cover transport vanes.

Feature benefits:

S700 variable-stream rotor

S700 variable-stream rotorFunctionality:

Fifteen cast-constructed threshing elements provide superior handling, improved durability and serviceability, and maintain excellent grain quality. The elements spiral around the rotor to move and control the material. In some harvesting conditions, 12 additional bolt-on threshing tines may be installed for increased material handling.

Rear discharge flights and a tapered rear cone improve material handoff to the rear discharge beater.

Electrically adjustable transport vanes allow operators to change the vane angle within the cab. Longer straw length can be accomplished when vanes are in the advanced position.

Electric actuator for adjustable vanes

Electric actuator for adjustable vanesCompare the specifications of up to 4 models

| Key Specs | s770-combine Current Model |

|---|---|

| Engine type | John Deere PowerTech™ PSS engine 9 L 548 cu in. |

| Rated power | 292 kW 391 hp |

| Fuel capacity | 950 L 250 gal. |

| Rotor length | 312 cm 123 in. |

| Rotor diameter | 76.2 cm 30 in. |

| Concave area | 1.1 m2 11.8 sq ft |

| Separating area | 1.54 m2 16.6 sq ft |

| Total cleaning area (louvered) | 5.1 m2 54.9 sq ft |

| Grain tank size | 10,600 L 300 bu |

| Unloading rate | 116.3 L/s 3.3 bu/sec |

| Engine | |

| Engine type | John Deere PowerTech PSS engine 9 L 548 cu in. |

| Emission level | Final Tier 4 / Tier 2 (Australia/New Zealand) |

| Rated speed | 2,200 rpm |

| Rated power | 292 kW 391 hp |

| Power boost @ rated speed | 25 kW 34 hp |

| Fuel capacity | 950 L 250 gal. |

| Engine family | |

| Feeding | |

| Drive type | Fixed or variable or multi-speed |

| Conveyor chain slat type | Cast iron |

| Width | 139.7 cm 55 in. |

| Length | 172.5 cm 67.9 in. |

| Feed Accelerator, Stone Trap (FAST) | Reverser Standard Standard |

| Threshing/ Separating | |

| Separator type | Rotary |

| Rotor length | 312 cm 123 in. |

| Rotor diameter | 76.2 cm 30 in. |

| Rotor speed range | 210-1,000 rpm |

| Concave area | 1.1 m2 11.8 sq ft |

| Separating area | 1.54 m2 16.6 sq ft |

| Discharge grate area | 0.36 m2 3.9 sq ft |

| Cleaning | |

| Front chaffer | 0.5 m2 5.4 sq ft |

| Front chaffer extension | |

| Pre cleaning | |

| Chaffer | 2.5 m2 26.9 sq ft |

| Sieve area | 2.1 m2 22.6 sq ft |

| Total cleaning area (louvered) | 5.1 m2 54.9 sq ft |

| Cleaning fan speed | 620-1,350 rpm |

| Grain handling | |

| Grain tank size | 10,600 L 300 bu |

| Unloading auger length | 6.9, 7.9 or 8.7 m 22.5, 26 or 28.5 ft |

| Unloading rate | 116.3 L/s 3.3 bu/sec |

| Base weight - less head | |

| Total machine | 18,950 kg 41,778 lb |

| Manufacturing location | |

| Country | USA, East Moline, Illinois |

The camera-ready feature is optional on all S700 Combines and provides factory-installed observation camera harnesses and brackets in the grain tank, on the unloading auger, and at the rear of the combine.

John Deere value:

Functionality:

Rearview camera location

Rearview camera location Unloading auger camera location

Unloading auger camera location Unloading auger camera location

Unloading auger camera location Grain tank camera location

Grain tank camera location Camera trigger menu

Camera trigger menu

NOTE: 4600 CommandCenter is capable of viewing up to four cameras simultaneously.

NOTE: Cameras are not included with factory-installed option. Please order cameras from Service Parts.

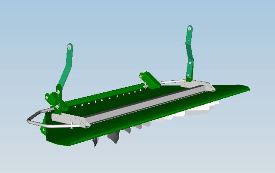

The Dyna-Flo Plus cleaning shoe is the heart of the S700 Combine cleaning system. The system is made up of a unique design consisting of aluminum and high-strength steel that reduces overall weight while maintaining overall strength. The Dyna-Flo Plus cleaning shoe also features an enhanced drive system that requires only one flywheel for optimal shoe performance and maximizes uptime.

Feature benefit:

Dyna-Flo Plus cleaning shoe

Dyna-Flo Plus cleaning shoe Enhanced drive system

Enhanced drive systemThe Dyna-Flo Plus cleaning system begins with conveyor augers located beneath the concave area, where the volume of threshed material is highest, to evenly move material onto the cleaning shoe (1). The deep auger troughs provide uniform distribution of material to the cleaning shoe with less bunching, even on sloping terrain and when harvesting up and down hills.

Dyna-Flo Plus cleaning shoe

Dyna-Flo Plus cleaning shoeOnce grain is on the cleaning shoe, the raised-center front chaffer cleans up to 40 percent of free grain before it reaches the main chaffer (3). High-velocity air from the cleaning fan elevates any light material traveling over the end of the front chaffer, resulting in more aggressive separation of chaff and increased cleaning performance (2). The main chaffer provides grain separation from chaff as the grain passes through the main chaffer to the sieve (4).

The sieve provides proper sizing of grain from material other than grain (5). Any grain that passes through the sieve is elevated to the grain tank while some grain or material other than grain flows to the tailings return system for reprocessing. On S760, and S770 Combines, the tailings material is directed back into the threshing section of the separator for additional threshing. The tailings material on the S780 and S790 Combines are directed to the active tailings return system for additional threshing, and then directed back on the return pan and then onto the main chaffer for additional cleaning (6).

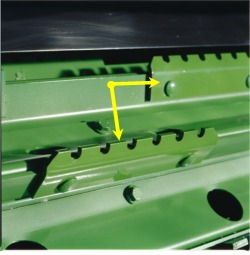

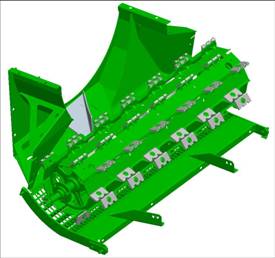

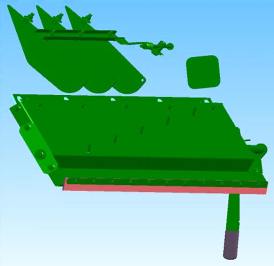

Parts included for side hill package

Parts included for side hill packageThe side hill performance package can improve combine performance on slopes up to 8 degrees (14 percent) by substantially reducing cleaning shoe grain loss to acceptable levels.

Feature benefit:

Functionality:

The side hill kit installed in the cleaning shoe of S700 Combines allows grain to be evenly distributed across the entire width of the shoe when harvesting in slopes. As grain moves to the rear of the combine, the dividers keep grain contained into four individual bays which prevents overloading one side of the cleaning shoe. Additionally, the rubber agitator paddles in each individual bay work with the oscillating motion of the cleaning shoe to move grain toward the center of each bay for increased utilization of the entire cleaning shoe width for increased performance and productivity.

Round-bar concaves are standard equipment on corn combines and are recommended for use in corn and soybeans. Additionally, they are recommended for use in specialty crops such as edible beans and food corn.

Feature benefit:

Round-bar multi-crop concave

Round-bar multi-crop concave

See concave recommendations to choose the concaves that are best for a grower's operation.

The front concave section is heat treated. All three sections are available to be heat treated as an option or in the extended-wear separator package.

Additional threshing tine base weldments for installation into the DensePack locations of a variable-stream rotor can only be used to improve material handling in some tougher conditions such as rice and grass seed harvest. This may decrease machine performance if used in dry, brittle-crop conditions.

Feature benefit:

Variable-stream rotor equipped with DensePack

Variable-stream rotor equipped with DensePack Grain wear plates

Grain wear plates Rice wear plates

Rice wear plates

Wear plate kits (grain versus rice) must be ordered separately through Service Parts.

Rear of rotor with discharge paddles

Rear of rotor with discharge paddlesRotor discharge flights are available for STS combines when operating in specialty crops. The discharge flights are recommended for use in crops such as sunflowers and edible beans when operating in conditions that require rotor threshing speeds below 300 rpm.

The discharge flights are designed to provide an aggressive push to the slow-moving crop material as it moves from the rotor housing into the discharge beater. The additional kick provided by the paddle design of the flighting significantly improves material flow and reduces possible plugging at the rear of the rotor at extremely low threshing speeds.

When operating in other crops where rotor speeds higher than 300 rpm are required (for example, soybeans, wheat, rice, etc.), it is recommended the discharge flights BE REMOVED to ensure adequate and even material flow through the rotor, as well as to provide better residue spread.

IMPORTANT: Discharge flight paddles are NOT recommended for use in heavy, damp wheat or rice crops.

The discharge flight is for use on any 9650 STS, 9750 STS, 9660 STS, 9760 STS, 9860 STS, 9670 STS, 9770 STS, and 9870 STS Combines and does not require the combine to be fitted with any particular configuration of rotor discharge housings.

NOTE: Two rotor discharge flight paddles for 9560 STS, 9570 STS, and S550 STS Combines, AH219961 and AH219962, can be ordered through Service Parts.

Round-bar concaves are standard equipment on corn combines and are recommended for use in corn and soybeans. Additionally, they are recommended for use in specialty crops such as edible beans and food corn.

Feature benefit:

Round-bar multi-crop concave

Round-bar multi-crop concave

See concave recommendations to choose the concaves that are best for a grower's operation.

The front concave section is heat treated. All three sections are available to be heat treated as an option or in the extended-wear separator package.

Small-wire concaves are standard equipment on small-grain combines and are recommended for use in wheat, barley, and other cereal crops. The small-wire concaves are recommended for use in specialty crops such as grass seed.

Feature benefits:

Small-wire concave for small grain

Small-wire concave for small grain

See concave recommendations to choose the concaves that are best for grower's operation.

The small-wire concaves are also available as an option with boronized treatment for extended-wear life. This process penetrates the surface of the concave with a layer of hard, wear-resistant material, extending the life of the concave up to twice as long, and is available in the extended-wear separator package.

IMPORTANT: Not recommended for use in corn.

Large-wire concaves are standard on S700 Rice Combines and available as an option on corn and small-grain combines. They are recommended for rice, sorghum, soybeans, and corn.

Feature benefit:

Large-wire concave

Large-wire concaveLarge-wire concaves are standard on S700 Rice Combines and available as an option on corn and small-grain combines.

They are recommended for rice, sorghum, soybeans, and corn.

See concave recommendations to choose the concaves that are best for grower's operation.

As an option, all three sections can be boronized for extended-wear life. This process penetrates the surface of the concave with a layer of hard, wear-resistant material, extending life up to twice as long.

Large-wire concaves are standard on S700 Rice Combines and available as an option on corn and small-grain combines. They are recommended for rice, sorghum, soybeans, and corn.

Feature benefit:

Large-wire concave

Large-wire concaveLarge-wire concaves are standard on S700 Rice Combines and available as an option on corn and small-grain combines.

They are recommended for rice, sorghum, soybeans, and corn.

See concave recommendations to choose the concaves that are best for grower's operation.

As an option, all three sections can be boronized for extended-wear life. This process penetrates the surface of the concave with a layer of hard, wear-resistant material, extending life up to twice as long.

This attachment is used for rice configured machines only. Rice performance enhancement package contains spike caps, and long threshing tines. When it is used in certain crop conditions, it may enhance the performance of the combine. Attachment includes instructions on how and when to use the components.

Spike caps

Spike caps Separator grate interrupters

Separator grate interrupters Long threshing tines

Long threshing tines Concave cover plates for round-bar concaves only

Concave cover plates for round-bar concaves onlyConcave sectionalized cover plates for round-bar concaves help to increase performance in the threshing area in tough conditions and can improve material distribution from the concaves to the cleaning system.

Concave cover plates for round-bar concaves only

Concave cover plates for round-bar concaves onlyConcave sectionalized cover plates for round-bar concaves help to increase performance in the threshing area in tough conditions and can improve material distribution from the concaves to the cleaning system.

Small-wire concaves are standard equipment on small-grain combines and are recommended for use in wheat, barley, and other cereal crops. The small-wire concaves are recommended for use in specialty crops such as grass seed.

Feature benefits:

Small-wire concave for small grain

Small-wire concave for small grain

See concave recommendations to choose the concaves that are best for grower's operation.

The small-wire concaves are also available as an option with boronized treatment for extended-wear life. This process penetrates the surface of the concave with a layer of hard, wear-resistant material, extending the life of the concave up to twice as long, and is available in the extended-wear separator package.

IMPORTANT: Not recommended for use in corn.

The rotary screen brush kit adds a series of brushes to the rotary screen. The brushes prevent debris from building up on the screen, allowing full air flow to the engine for cooling.

Contoured serrated wear strips

Contoured serrated wear strips Regular straight serrated wear strips

Regular straight serrated wear stripsThe serrated feed accelerator wings have a smooth contoured back to provide fast yet gentle crop handling while also featuring serrated edges for positive crop movement in viney crops such as edible beans.

The updated feed accelerator wings are recommended in place of the optional smooth accelerator wear strips attachment because they help to provide excellent grain quality without compromising feeding performance in edible beans.

Stone trap and stone trap handle

Stone trap and stone trap handle

The stone trap protects the combine's interior area by effectively catching stones deflected by the feed accelerator into the stone dump area before they enter the TriStream™ feed section.

Base Equipment On: S-Series Combines

An expanded stone trap door with a two-piece front feed floor is available as a field-installed bundle. This bundle replaces the standard one-piece feed floor.

When harvesting crops such as corn, food corn, popcorn, and small grains, the front-piece floor section remains bolted in place. This allows 9 in. of opening across the width of the machine.

In rocky conditions such as beans and edible beans, the front floor section is removed to provide 11.5 in. of open area to the larger stone trap, allowing improved rock protection (22 percent increase in stone trap area).

Please refer to the chart below for retro-fit information

Two-speed feed accelerator handle

Two-speed feed accelerator handle The slow-speed drive reduces the standard two-speed feed accelerator from 450 rpm/800 rpm to 320 rpm/770 rpm.

These lower speeds allow the feed accelerator to provide more gentle grain handling in delicate specialty crops such as edible beans, food corn, or popcorn.

Having the slow-speed feed accelerator drive available as a factory-installed option allows those who plan on using this drive for harvesting all their crops to save the cost of discarding the standard feed accelerator drive parts in the field.

Smooth-wear strips on feed accelerator

Smooth-wear strips on feed acceleratorThe smooth-wear strips provide optimum grain quality in speciality crops such as popcorn and food corn. The bundle includes set of 30 wear strips to replace standard-equipment serrated wear strips.

Tine FAST feed accelerator

Tine FAST feed accelerator Combed floor

Combed floorThe enhanced rice performance attachment is recommended for improved harvesting capacity when rice conditions may be limited due to slugs and heavy loads from straw intake while harvesting.

This attachment provides smoother feeding and better material handling, along with increased rice harvesting capacity.

The attachment includes the tine feed accelerator and stone trap (FAST) system, combed floor, threshing tines, discharge paddles, and directions on how to move the existing feed accelerator to the discharge location.

Threshing tines

Threshing tines Discharge beater

Discharge beater Grain tank level sensor

Grain tank level sensorThe fast, easy way to let the operator know the combine’s grain tank is full when harvesting on side hills.

Functionality:

An additional grain tank level indicator is available to help detect a full grain tank.

The beacon lights are also activated when the combine is in road transport mode.

When harvesting in wet or dirty conditions, the steel-paddle tailings elevator can be installed to remove the build-up of dirt and debris.

ActiveYield delivers automatic yield calibrations to the operator without spending time manually performing yield calibrations.

Feature benefit:

Functionality:

ActiveYield eliminates time-consuming manual yield calibrations and replaces them with automated sensors that calibrate the machine by measuring the grain as the tank fills. This enables decisions to be made in real time without leaving the cab.

ActiveYield sensors in grain tank

ActiveYield sensors in grain tankWhen the ActiveYield option is enabled and the Terrain Compensation Module (TCM) in the StarFire™ 3000 or StarFire 6000 Receiver has been calibrated, ActiveYield is ready to go to work. As grain is harvested and enters the tank, the three sensors within the grain tank collectively measure the grain as it piles over the cross auger covers. If all conditions are acceptable (header and separator on, grain is flowing, and machine level is within 4 degrees) load collection occurs from 900 through 3000 kg (2000 through 6600 lb).

Any pitch and roll of more than 4 degrees from center during load collection will cause the system to reject that load due to the grain pile shifting in the tank. A new calibration load starts once grain is below the sensors on the cross auger covers.

Stored calibration loads are replaced by new ones as the system continues to collect data. The system may be disabled at any time by accessing the moisture setup page and unchecking the ActiveYield box if manual yield calibration is desired.

ActiveYield calibration location

ActiveYield calibration location ActiveYield Information

ActiveYield InformationActiveYield is available for model year 2016 through model year 2019 S760, S770, S780, and S790 Combines and requires the 4600 CommandCenter™ Display, GreenStar™ 3 2630 Display, or GreenStar 3 CommandCenter. Additionally, a StarFire 3000 or 6000 Receiver must be installed on the combine with the TCM calibrated for ActiveYield to detect machine pitch correctly. Manual yield calibration is not required as each crop has a built-in default value.

Harvest Doc™ system yield data collected by an ActiveYield system is only compatible with the John Deere Operations Center. John Deere does not guarantee compatibility of ActiveYield collected documentation with John Deere APEX™ software or third-party software systems.

This bolt-on access platform attachment is required for S700-Series Combines that are ordered less wheels and tires and later equipped with single front drive tires. Refer to the tire compatibility charts in the Agricultural Sales Manual for specific drive tire sizes and compatibility information for the 230-mm (9-in) bolt-on access platform. This attachment includes all the parts to install this ladder extension on S700-Series Combines.

This bolt-on access platform attachment is required for S-Series Combines that are ordered less wheels and tires and later equipped with single front drive tires. Refer to the tire compatibility charts in the Agricultural Sales Manual for specific drive tire sizes and compatibility information for the 330 mm bolt-on access platform. This attachment includes all the parts for this specific ladder extension installation.

This bolt-on access platform attachment is required for S-Series Combines that are ordered less wheels and tires and later equipped with either dual front or single drive tires with axle spacers. Refer to the tire compatibility charts in the Agricultural Sales Manual for specific dual and single drive tire sizes and compatibility information for the dual tire platform extension.

This 1554-mm (61.2-in.) length ladder is required for S-Series Combines that are ordered less wheels and tires and later equipped with front drive tires for S-Series Combines that have a static loaded radious (SLR) of 910 mm (36 in.). Refer to the tire compatibility charts in the Agricultural Sales Manual for specific drive tire sizes and compatibility information for the long length 1554-mm (61.2-in.) ladder.

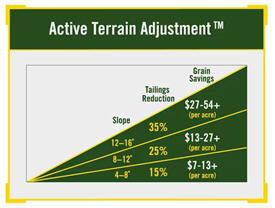

Active Terrain Adjustment is a system that enhances grain quality and reduces grain loss when harvesting on ascending or descending hills. The feature automatically adjusts the combine’s sieve and chaffer openings and carefully controls the cleaning fan speed, stabilizing tailings levels and ensuring a clean grain tank sample.

Feature benefit:

Achieves same loss level as on level land conditions (on hills up to 10 degrees)

Tailings reductions by up to 35 percent on 8-12-degree inclines

Automatic settings adjustments on hills

Active Terrain Adjustment slope

Active Terrain Adjustment slopeFunctionality:

Order Active Terrain Adjustment as a factory-installed option or as an attachment for field installation on model year 2016 machines and newer (PIN 785000 -). The feature can be used in both coarse and small grains in all terrain, but will excel especially on hills.

Active Terrain Adjustment pitch sensor

Active Terrain Adjustment pitch sensor Active Terrain Adjustment cleaning fan actuator

Active Terrain Adjustment cleaning fan actuatorWhen the machine starts an uphill climb, Active Terrain Adjustment will slow the cleaning fan down and open the chaffer and sieve elements. As the machine descends a hill, the cleaning fan speed will increase and the chaffer and sieve elements will close to decrease grain loss and prevent shoe loading.

ActiveYield delivers automatic yield calibrations to the operator without spending time manually performing yield calibrations.

Feature benefit:

Functionality:

ActiveYield eliminates time-consuming manual yield calibrations and replaces them with automated sensors that calibrate the machine by measuring the grain as the tank fills. This enables decisions to be made in real time without leaving the cab.

ActiveYield sensors in grain tank

ActiveYield sensors in grain tankWhen the ActiveYield option is enabled and the Terrain Compensation Module (TCM) in the StarFire™ 3000 or StarFire 6000 Receiver has been calibrated, ActiveYield is ready to go to work. As grain is harvested and enters the tank, the three sensors within the grain tank collectively measure the grain as it piles over the cross auger covers. If all conditions are acceptable (header and separator on, grain is flowing, and machine level is within 4 degrees) load collection occurs from 900 through 3000 kg (2000 through 6600 lb).

Any pitch and roll of more than 4 degrees from center during load collection will cause the system to reject that load due to the grain pile shifting in the tank. A new calibration load starts once grain is below the sensors on the cross auger covers.

Stored calibration loads are replaced by new ones as the system continues to collect data. The system may be disabled at any time by accessing the moisture setup page and unchecking the ActiveYield box if manual yield calibration is desired.

ActiveYield calibration location

ActiveYield calibration location ActiveYield Information

ActiveYield InformationActiveYield is available for model year 2016 through model year 2019 S760, S770, S780, and S790 Combines and requires the 4600 CommandCenter™ Display, GreenStar™ 3 2630 Display, or GreenStar 3 CommandCenter. Additionally, a StarFire 3000 or 6000 Receiver must be installed on the combine with the TCM calibrated for ActiveYield to detect machine pitch correctly. Manual yield calibration is not required as each crop has a built-in default value.

Harvest Doc™ system yield data collected by an ActiveYield system is only compatible with the John Deere Operations Center. John Deere does not guarantee compatibility of ActiveYield collected documentation with John Deere APEX™ software or third-party software systems.

Deflector for PowerCast tailboard

Deflector for PowerCast tailboard

This is the seal that is needed convert to the PowerCast tailboard.

Distribution bundle/deflector for premium residue

Distribution bundle/deflector for premium residue

Is recommended to use when you have uneven residue distribution as a result of uneven material coming from the discharge beater. This bundle will help to improve that distribution as it’s moved into the residue system.

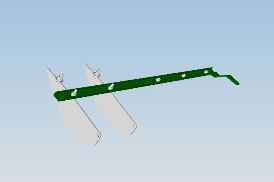

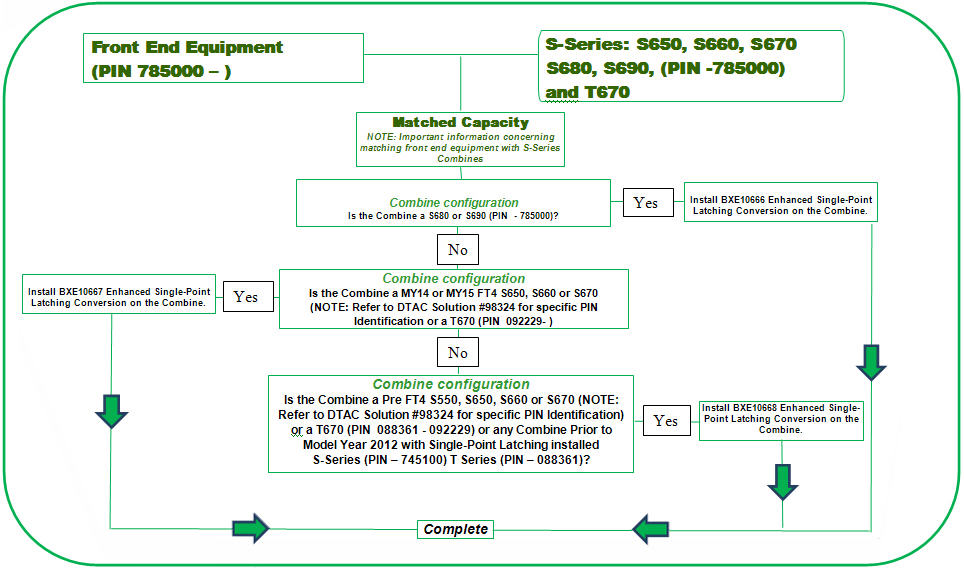

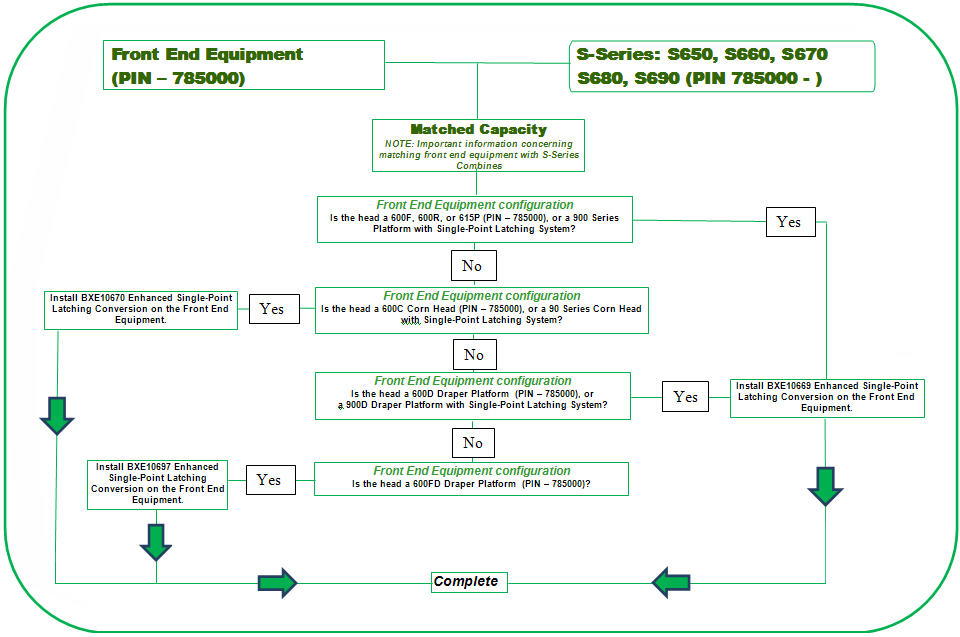

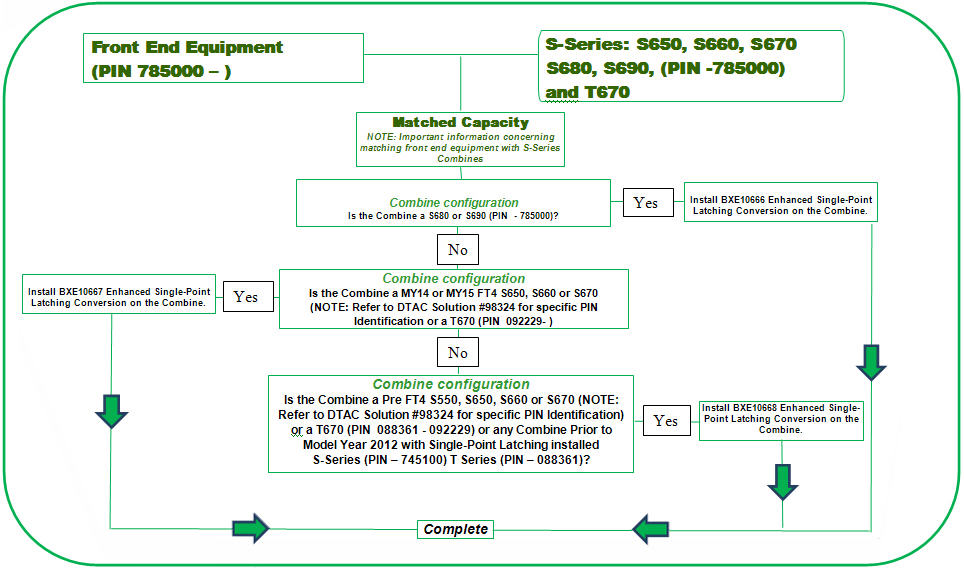

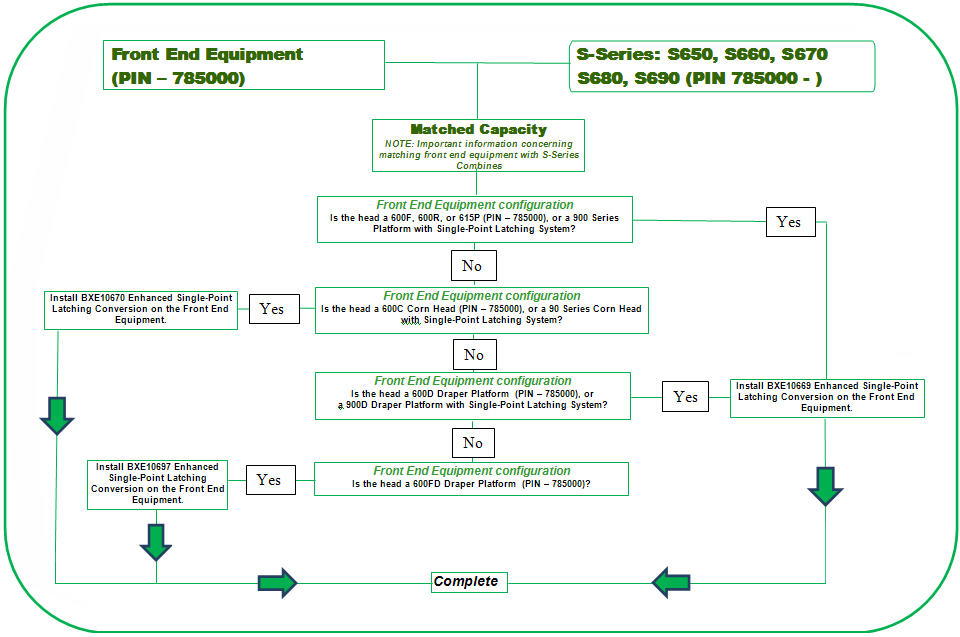

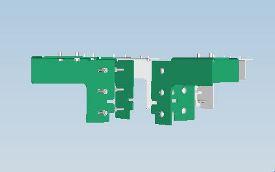

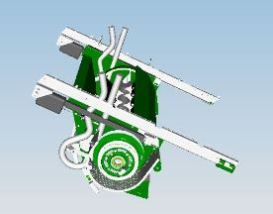

Enhanced single-point latching system

Enhanced single-point latching systemJohn Deere’s single-point header latching system provides combine operators a fast and easy method for connecting all front-end equipment. One easy motion of the lever connects the electrical and hydraulic circuits along with header retaining pins.

The enhanced single-point latching system, starting in model year 2016, will include a valve assembly mounted to all platform and corn head back sheets. These assemblies will include an orifice valve unique to the header type as well as a pressure override valve. Together, these ensure optimum performance and reliability of header hydraulic functions.

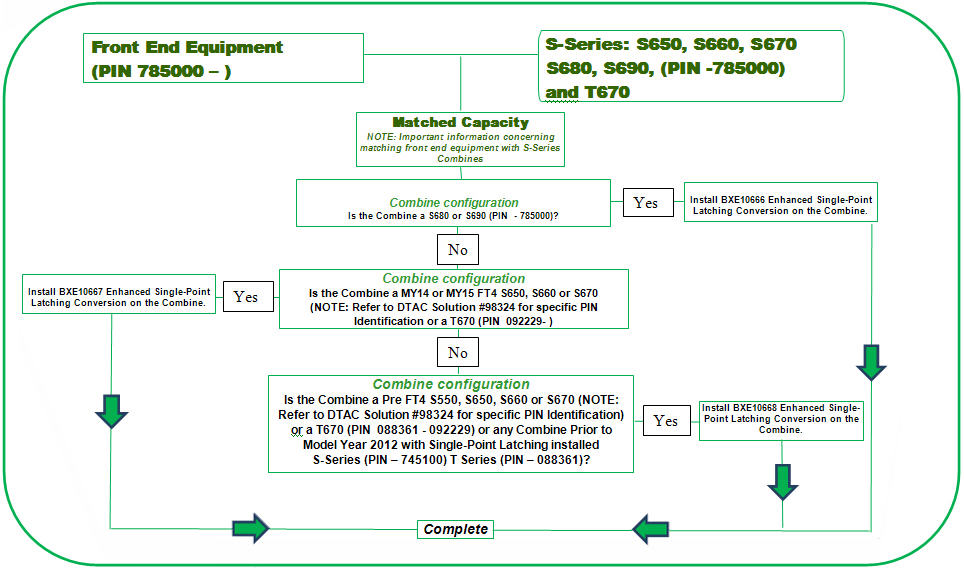

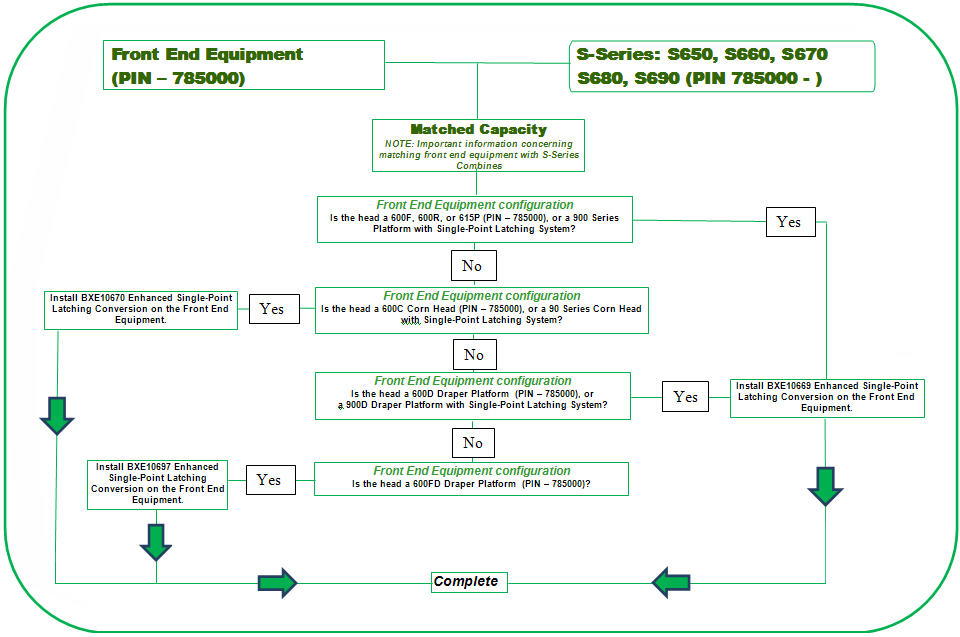

Compatibility for prior headers or combines to model year 2016 equipment is provided by attachments specific to the header and combine being used. Refer to the chart below for compatibility information.

Six different attachments cover the compatibility between new and used combines and front-end equipment. The attachments are BXE10667, BXE10666, BXE10668, BXE10670, BXE10697, and BXE10669.

Enhanced single-point latching system

Enhanced single-point latching systemJohn Deere’s single-point header latching system provides combine operators a fast and easy method for connecting all front-end equipment. One easy motion of the lever connects the electrical and hydraulic circuits along with header retaining pins.

The enhanced single-point latching system, starting in model year 2016, will include a valve assembly mounted to all platform and corn head back sheets. These assemblies will include an orifice valve unique to the header type as well as a pressure override valve. Together, these ensure optimum performance and reliability of header hydraulic functions.

Compatibility for prior headers or combines to model year 2016 equipment is provided by attachments specific to the header and combine being used. Refer to the chart below for compatibility information.

Six different attachments cover the compatibility between new and used combines and front-end equipment. The attachments are BXE10667, BXE10666, BXE10668, BXE10670, BXE10697, and BXE10669.

S-Series standard straw spreader

S-Series standard straw spreaderThe twin-disc straw spreader system uses two large impellers to ensure uniform distribution of material from the separator and cleaning system. The spreader is recommended for use when tillage practices do not dictate fine sizing of crop residue.

When harvesting in wet or dirty conditions, the steel-paddle tailings elevator can be installed to remove the build-up of dirt and debris.

The large tool cabinet is available on model year 2019 and newer combines models.

Two tool cabinet decks

Two tool cabinet decks Tool cabinet storage space

Tool cabinet storage spaceAsh tray and cigarette lighter attachment for S-Series cabs

Axle spacers enable specific tire spacing for S-Series Combines. Reference the attached Ag Sales Manual S-Series tire spacing chart for specific tire, tire spacing, and recommended axle spacer information. The axle spacer attachments include axle spacers, attaching hardware, truss rods, couplers, and shaft extensions. Ladder extensions are typically required and ordered separately to provide the necessary clearance between the tires and ladder.

Please reference the following documents for more detailed information.

Axle spacers enable specific tire spacing for S-Series Combines. Reference the attached Ag Sales Manual S-Series tire spacing chart for specific tire, tire spacing, and recommended axle spacer information. The axle spacer attachments include axle spacers, attaching hardware, truss rods, couplers, and shaft extensions. Ladder extensions are typically required and ordered separately to provide the necessary clearance between the tires and ladder.

Please reference the following documents for more detailed information.

Axle spacers enable specific tire spacing for S-Series Combines. Reference the attached Ag Sales Manual S-Series tire spacing chart for specific tire, tire spacing, and recommended axle spacer information. The axle spacer attachments include axle spacers, attaching hardware, truss rods, couplers, and shaft extensions. Ladder extensions are typically required and ordered separately to provide the necessary clearance between the tires and ladder.

Please reference the following documents for more detailed information.

Axle spacers enable specific tire spacing for S-Series Combines. Reference the attached Ag Sales Manual S-Series tire spacing chart for specific tire, tire spacing, and recommended axle spacer information. The axle spacer attachments include axle spacers, attaching hardware, truss rods, couplers, and shaft extensions. Ladder extensions are typically required and ordered separately to provide the necessary clearance between the tires and ladder.

Please reference the following documents for more detailed information.

Axle spacers enable specific tire spacing for S-Series Combines. Reference the attached Ag Sales Manual S-Series tire spacing chart for specific tire, tire spacing, and recommended axle spacer information. The axle spacer attachments include axle spacers, attaching hardware, truss rods, couplers, and shaft extensions. Ladder extensions are typically required and ordered separately to provide the necessary clearance between the tires and ladder.

Please reference the following documents for more detailed information.

Axle spacers enable specific tire spacing for S-Series Combines. Reference the attached Ag Sales Manual S-Series tire spacing chart for specific tire, tire spacing, and recommended axle spacer information. The axle spacer attachments include axle spacers, attaching hardware, truss rods, couplers, and shaft extensions. Ladder extensions are typically required and ordered separately to provide the necessary clearance between the tires and ladder.

Please reference the following documents for more detailed information.

Axle spacers enable specific tire spacing for S-Series Combines. Reference the attached Ag Sales Manual S-Series tire spacing chart for specific tire, tire spacing, and recommended axle spacer information. The axle spacer attachments include axle spacers, attaching hardware, truss rods, couplers, and shaft extensions. Ladder extensions are typically required and ordered separately to provide the necessary clearance between the tires and ladder.

Please reference the following documents for more detailed information.

Axle spacers enable specific tire spacing for S-Series Combines. Reference the attached Ag Sales Manual S-Series tire spacing chart for specific tire, tire spacing, and recommended axle spacer information. The axle spacer attachments include axle spacers, attaching hardware, truss rods, couplers, and shaft extensions. Ladder extensions are typically required and ordered separately to provide the necessary clearance between the tires and ladder.

Please reference the following documents for more detailed information.

Axle spacers enable specific tire spacing for S-Series Combines. Reference the attached Ag Sales Manual S-Series tire spacing chart for specific tire, tire spacing, and recommended axle spacer information. The axle spacer attachments include axle spacers, attaching hardware, truss rods, couplers, and shaft extensions. Ladder extensions are typically required and ordered separately to provide the necessary clearance between the tires and ladder.

Please reference the following documents for more detailed information.

S700 rear-wheel assist motor

S700 rear-wheel assist motor Continue harvesting, even in muddy conditions

Continue harvesting, even in muddy conditionsFeature benefit:

Functionality:

Specifications of the 2294-cc (140-cu in.) 4WD system include:

On all ProDrive™ transmission machines, low-speed 4WD engagement is limited to 10 km/h (6.2 mph) and high-speed 4WD engagement is limited to 15.9 km/h (9.9 mph) with maximum speed up to 20 km/h (12.4 mph).

S700 rear-wheel assist motor

S700 rear-wheel assist motor Continue harvesting, even in muddy conditions

Continue harvesting, even in muddy conditionsFeature benefit:

Functionality:

Specifications of the 2294-cc (140-cu in.) 4WD system include:

On all ProDrive™ transmission machines, low-speed 4WD engagement is limited to 10 km/h (6.2 mph) and high-speed 4WD engagement is limited to 15.9 km/h (9.9 mph) with maximum speed up to 20 km/h (12.4 mph).

Axle spacers enable specific tire spacing for S-Series Combines. Reference the attached Ag Sales Manual S-Series tire spacing chart for specific tire, tire spacing, and recommended axle spacer information. The axle spacer attachments include axle spacers, attaching hardware, truss rods, couplers, and shaft extensions. Ladder extensions are typically required and ordered separately to provide the necessary clearance between the tires and ladder.

Please reference the following documents for more detailed information.

Enhanced single-point latching system

Enhanced single-point latching systemJohn Deere’s single-point header latching system provides combine operators a fast and easy method for connecting all front-end equipment. One easy motion of the lever connects the electrical and hydraulic circuits along with header retaining pins.

The enhanced single-point latching system, starting in model year 2016, will include a valve assembly mounted to all platform and corn head back sheets. These assemblies will include an orifice valve unique to the header type as well as a pressure override valve. Together, these ensure optimum performance and reliability of header hydraulic functions.

Compatibility for prior headers or combines to model year 2016 equipment is provided by attachments specific to the header and combine being used. Refer to the chart below for compatibility information.

Six different attachments cover the compatibility between new and used combines and front-end equipment. The attachments are BXE10667, BXE10666, BXE10668, BXE10670, BXE10697, and BXE10669.

Paddles for APC corn kit

Paddles for APC corn kit Paddles for APC corn kit

Paddles for APC corn kitThe Advanced PowerCast tailboard corn kit is recommended for combines that are equipped with the Advanced PowerCast tailboard during the corn harvest. The tailboard kit prevents damage to the straw paddled by large corn cobs and other foreign material. This attachment will improve distribution and wear characteristics of the Advanced PowerCast system when used in corn.

Overshot beater corn kit cover

Overshot beater corn kit cover Overshot beater corn kit cover

Overshot beater corn kit coverThe overshot beater corn kit attachment is ideal for combines that are equipped with the premium residue tailboard during corn harvest. This attachment will protect the cleaning shoe from damage from cobs that can be thrown by the overshot beater.

Fine-cut chopper with vane tailboard outlet

Fine-cut chopper with vane tailboard outletThis attachment is needed when converting from a less-residue option or straw spreaders to a fine-cut chopper. The S-Series straw chopper provides sizing and spreading of residue material across the entire width of the platform cutting width.

S-Series standard straw spreader

S-Series standard straw spreaderThe twin-disc straw spreader system uses two large impellers to ensure uniform distribution of material from the separator and cleaning system. The spreader is recommended for use when tillage practices do not dictate fine sizing of crop residue.

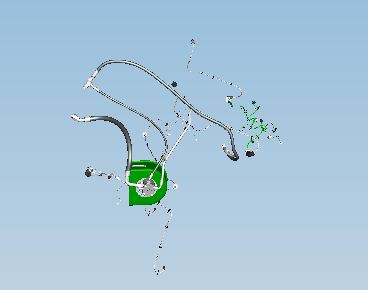

Hydraulics and electrics for Advanced PowerCast

Hydraulics and electrics for Advanced PowerCast

This attachment is for the hydraulic and electrics required for the Advanced PowerCast conversion.

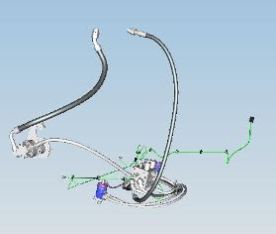

Hydraulics and electrics for spreaders

Hydraulics and electrics for spreaders

The twin-disc straw spreader system uses two large impellers to ensure uniform distribution of material from the separator and cleaning system. The spreader is recommended for use when tillage practices do not dictate fine sizing of crop residue.

Straw spreader options:

1. Standard straw spreader

2. Widespread straw spreader (not available on the S650)

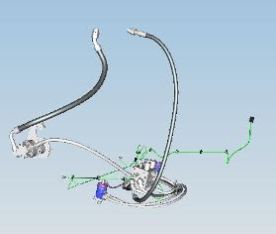

Hydraulics and electrics for spreaders

Hydraulics and electrics for spreaders

The twin-disc straw spreader system uses two large impellers to ensure uniform distribution of material from the separator and cleaning system. The spreader is recommended for use when tillage practices do not dictate fine sizing of crop residue.

Straw spreader options:

1. Standard straw spreader

2. Widespread straw spreader (not available on the S650)

Hydraulics and electrics for PowerCast

Hydraulics and electrics for PowerCast

This attachment is the hydraulic and electrics required for the PowerCast conversion.

PowerCast tailboard

PowerCast tailboard S680 with PowerCast tailboard

S680 with PowerCast tailboardTo better manage residue distribution with wider platforms, the PowerCast tailboard spreads residue 9.1 m (30 ft) and wider. This feature spreads residue evenly which helps set the stage for even crop emergence once planted, especially in no-till farming practices.

The PowerCast tailboard is a hydraulically powered tailboard assembly that mounts to the rear of the chopper. Two hydraulically driven, counter-rotating discs with paddles are mounted in the tailboard. Crop is discharged from the chopper to the spinning discs, where the velocity of the residue is increased so it can be distributed across the platform cut width, as desired. The distribution discs are driven by the same pump, and the speed is controlled by a button on the CommandTouch™ armrest.

Standard deflectors

Standard deflectors

This attachment is for producers moving from straw spreaders/less residue to a deluxe residue system equipped with a vane tailboard.

Manual vane tailboard

Manual vane tailboard Manual vane tailboard mounted

Manual vane tailboard mountedThe manually adjustable vane tailboard design provides a residue spread pattern for platform cut widths up to and including 9.14 m (30 ft).

The manually adjustable vane tailboard allows simple vane angle adjustments from the ground. Manually adjust the vane position, as required, to meet the desired spread width.

© COPYRIGHT 2025 LEGACY EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By