Premium lights

Premium lights

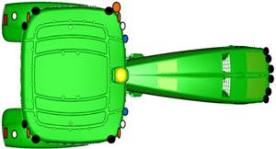

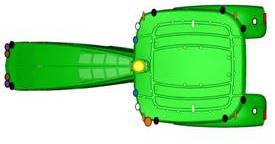

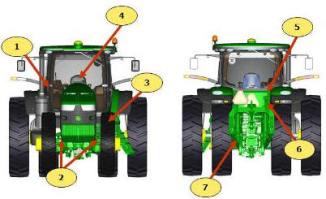

The 7R, 8R, and 8RT Series Tractors feature two lighting package options:

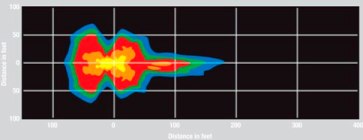

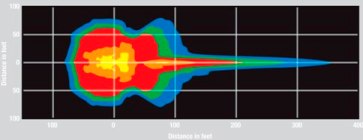

The cab lighting pattern provides 330 degrees of coverage while the hood lighting provides the remaining 30 degrees for completely programmable 360-degree, stadium-style lighting. This ensures there are no dead zones or lighting adjustments needed. The lighting configurations are available to match various applications and ensure maximum around-the-clock productivity.

Bulb housings are large, allowing for optimum total lumens and available light. The standard lighting packages use 65-W halogen bulbs, whereas the premium lighting package uses light-emitting diode (LED) lights. In the premium lighting package, these tractors take advantage of the high-performing and efficient LED technology.

The low- and high-beam driving/work lights are adjustable. Please refer to the electrical section in the operator’s manual for complete details on adjusting lights.

7R/8R/8RT lighting

7R/8R/8RT lighting

Yellow circles

Red circles

Blue circles

Orange circles

|

Standard lighting (8R)

Standard lighting (8R) Standard lighting (7R)

Standard lighting (7R)Six front grill-mounted lights:

10 cab roof-mounted lights:

Other lights:

Plus these lights:

Eight front grill-mounted lights:

12 cab roof-mounted lights:

Other lights:

The premium lighting package replaces all previous halogen and HID lights with LED lights. The only lights that are not LED are the low-beam driving lights, they remain halogen. This allows each LED light to work at a lower temperature and no one light works harder than any other. The uniformity in LED coverage allows only one type of light output surrounding the tractor.

The lighting pattern in the premium package provides industry-leading performance in nighttime visibility. LED bulbs provide maximum brightness and a true color output for excellent field definition that is easy on the operator's eyes.

The LED lights provide 40 percent greater coverage width and 10 percent more light coverage in the rear. LED lighting packages use 45 percent less amps than standard halogen lights and have an increased life expectancy over HID lights which leads to lower costs of ownership over the life of the tractor.

NOTE: Lighting packages may vary depending on region.

Lighting mode selector

Lighting mode selector

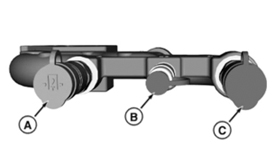

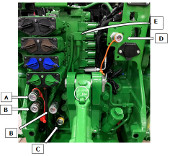

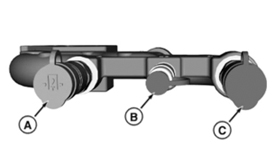

Operators can quickly select a lighting mode on the steering console:

The CommandCenter™ display

The CommandCenter™ displayThe CommandCenter display allows operators to customize light settings. Operators can select only the lights they need or want for a given application and store these settings. The operator-programmed configurations can then be turned on or off with the push of a button on the CommandARM™ controls.

NOTE: Road/loader lights are also referred to as high-mounted driving lights for use in front hitch applications that obscure the headlights. See the Attachments section.

The battery power saver feature is also standard. When the engine is off and the outside lights have been left on, this feature is designed to avoid battery run down.

After the lights have been left on for 30 minutes and the key is in the off position, the lights cycle or blink on and off five times as an alert. The lights continue to illuminate for one more minute and then automatically shut off to protect the battery.

Field-installed options are also available. To find this information, use the Build Your own Configurator application for US/Canada or Build & Price in John Deere Sales Centre for Australia/NZ.

Another feature is programmable exit lighting. Exit lighting allows the lights outside the cab to stay on for up to 300 seconds. They can be programmed in increments from 0 to 300 seconds.

Refer to the operator’s manual for complete instructions on programming field, driving, and exit lighting.

| Option code | Description |

| 7201 | Standard lighting |

| 7206 | Premium lighting |

The steering system uses load sensing of hydraulic pressure required to efficiently complete the designated tasks. The pressure- and flow- compensating pump produces excellent stationary or creeping ground speed steering response to handle demanding applications.

7R in transport

7R in transport

With ACS, John Deere has designed one of the most robust and full-encompassing steering system in the industry. Whether in the field or on the road, ACS reduces steering effort, which can result in reduced operator fatigue and can improve operator comfort.

There are four key features of the ACS system:

Dynamic road wheel offset

Variable ratio steering

Elimination of steering slop and hand wheel drift

Variable effort steering

The ACS system is fail operational, which means steering is still functional in the event of any single-point failure. John Deere has gone to great lengths to help ensure the operator can steer the tractor if something goes wrong in the steering system.

For example, if the primary controller fails, a second controller takes over. If power from the alternator is lost, the battery resumes control. If the engine quits running and is unable to supply hydraulic oil to the system, an electric-driven backup pump is used to supply the oil.

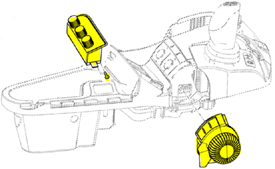

ACS components

ACS components

The ACS system consists of several key components:

| Option code | Description |

| 1833 | John Deere ActiveCommand Steering (ACS) |

ActiveSeat and controls

ActiveSeat and controls

John Deere’s ActiveSeat utilizes electrohydraulic technology in combination with air suspension, providing the operator with enhanced ride quality over standard air-suspension seats.

Operator movements are monitored in order to reduce vertical movement. An ActiveSeat suspension can isolate the operator from up to 90 percent of vertical movements typically seen in tractor applications.

The system uses a hydraulic cylinder that is connected to a control valve assembly. Electrohydraulic valves located in the control valve assembly automatically react to inputs from two sensors, a position sensor and an accelerometer. Inputs from these two sensors control oil flow from the tractor to the hydraulic cylinder to reduce the vertical movement of the operator.

ActiveSeat left armrest

ActiveSeat left armrest

The John Deere ActiveSeat has many of the same features of the ComfortCommand™ seat with the addition of a ride firmness switch. The ride firmness switch is located on the left-hand armrest and replaces the suspension shock-dampening seat attenuation lever on the front right-hand side of the ComfortCommand seat controls.

The ride firmness switch has three positions: plus, minus, and mid position. The three positions provide three different levels of seat performance:

The ActiveSeat is also available as a heated leather seat for increased comfort and easier cleaning. For tractor applications where operating speed is not limited by the implement, the ActiveSeat can allow for faster field speeds and increased overall comfort and productivity.

NOTE: The John Deere ActiveSeat is not available on track tractors.

| Option code | Description |

| 2061 | Premium CommandView III Cab with Active Seat |

7R e23 transmission

7R e23 transmission

The e23 transmission delivers smooth shifting and intuitive controls with Efficiency Manager™ feature in a reliable 23-speed PowerShift™ transmission. The e23 transmission is available for all 7R, 8R, and 8RT Series Tractors.

The e23 has evolved from more than 50 years of John Deere PowerShift technology. With more automatic features, the e23 is easy to operate for all levels of operator experience. For more advanced operators looking to customize the transmission to best fit their operation, the e23 offers a custom mode.

As the next generation of PowerShift technology, e23 delivers the strength to handle sudden, high-torque power loads while maintaining responsive, quick, and smooth shifts. The e23 with Efficiency Manager provides improved fluid efficiency and overall productivity with limited input from the operator.

e23 options

Even gear spacing for optimal performance

The e23 has 23 forward gears and 11 reverse gears, which are all evenly spaced. Forward gears are spaced 15 percent apart, while reverse gears are spaced approximately 30 percent apart, providing operators smooth shifting between gears. Even spacing improves efficiency and allows for smooth, automated shifts when using Efficiency Manager. The e23 can reach maximum forward ground speed in gear F20. As a result, gears F21-F23 maintain maximum ground speed at reduced engine rpms to save fuel.

e23 controls

The e23 is available with either a right-hand or left-hand reverser.

Right-hand reverser

Right-hand reverser

Right-hand reverser

A convenient, right-hand reverser is available with the e23 transmission. The reverser is located on the CommandARM™ as shown above.

Right-hand reverser equipped models use three main controls to operate the tractor:

The right-hand reverser control strategy combines speed control and direction control into one multi-function lever that is conveniently located on the CommandARM. This is a good choice for most common field applications since tractor speed and direction are not constantly being adjusted by the operator.

Left-hand reverser

Left-hand reverser Left-hand transmission lever

Left-hand transmission leverAn easy-to-use left-hand reverser is available with the e23 transmission and includes the same functions as the right-hand reverser. The reverser control is located at the 10 o’clock position on the steering column for intuitive control.

The five-position, left-hand reverser column incorporates the following controls:

Left-hand reverser equipped models use four main controls to operate the tractor:

The left-hand reverser control strategy separates the direction control lever from the speed/gear control lever on the CommandARM. This strategy is a good choice for operations requiring the right hand to run multiple operations on the CommandARM or applications requiring constant directional changes like loader work.

Determining which reverser is best suited for a specific operator depends on a few key factors. Consider the following to help choose between a left- or right-hand reverser.

Producers primarily in row-crop applications using features like AutoTrac™ assisted steering system or operating with the seat swiveled to the right for easy access to monitors and displays might find the right-hand reverser more convenient. Speed and directional controls are in one location on the CommandARM.

The electrohydraulically controlled brakes on e23-equipped tractors have an integrated AutoClutch function.

Braking can be done on flat ground or steep slopes simply by using the brake pedals; it is not necessary to depress the clutch.

|

| Foot brake with integrated AutoClutch |

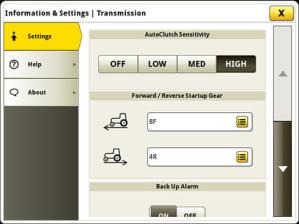

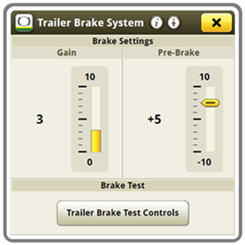

AutoClutch sensitivity can be adjusted through the Generation 4 CommandCenter™ display. AutoClutch can be deactivated on e23 transmissions as well; however, it will be reactivated after every key start.

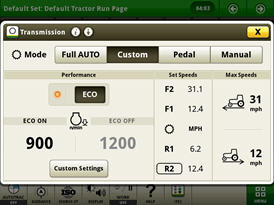

e23 custom transmission page

e23 custom transmission page

Custom mode allows operators to adjust operating parameters to meet their specific operation. Just like full AUTO mode, custom mode shifts set speeds meaning the transmission may not necessarily shift gears each time the lever is bumped. Efficiency manager is engaged automatically in custom mode.

During transport, it may be desirable to use the AutoClutch feature to stop the tractor when approaching an intersection or turn. Braking the tractor using the AutoClutch at high ground speed and engine speed will require high brake-pedal force.

Rather than using AutoClutch alone, reduce the engine rpm and reduce the e23 to a slower commanded speed before applying the AutoClutch. This will help to reduce the force needed to stop the tractor with the AutoClutch. The tractor will accelerate to the previously commanded speed upon release of the AutoClutch, repositioning of the hand throttle and increasing the commanded speed.

NOTE: The preferred method of stopping heavy towed loads is to reduce the e23 commanded speed and lower engine rpm first, and then depress both brake pedals. (Brake pedals should be locked together.)

Individual brake pedals can be used to assist slow-speed off-road turning, such as hooking up to an implement. At low idle, the AutoClutch feature will stop the tractor if the operator depresses only one brake pedal.

To assist in hooking up an implement, depress either brake pedal while slowly increasing engine speed until the desired turn is achieved. Returning engine speed to a low idle while continuing to depress one brake pedal will slow the tractor to a stop.

254-mm (10 in.) Generation 4 CommandCenter

254-mm (10 in.) Generation 4 CommandCenter

The CommandCenter is the central information system for tractors and allows the operator to program various settings tailored to a specific operation.

To access the tractor’s transmission settings, press the transmission shortcut button on the CommandCenter shortcut bar.

|

| CommandCenter transmission shortcut button |

Operating modes

The e23 application settings employ three modes to take full advantage of the engine-transmission communication: full auto mode, custom mode, and manual mode.

Full auto main page

Full auto main page

Full AUTO mode enables the tractor to make adjustments to the transmission operating mode automatically, based on engine and transmission speed and the load on the tractor. This means the tractor will shift up and throttle back automatically to reach the desired ground speed efficiently. Operators have the ability to set the maximum forward and reverse speeds for the tractor in their particular application.

When shifting in full AUTO mode, the transmission shifts set speeds, meaning the transmission may not necessarily shift gears each time the lever is bumped. Efficiency Manager is automatically engaged while operating in full AUTO mode. As a result, shifting will not take the tractor out of Efficiency Manager in full AUTO mode.

Additional transmission settings can be customized to the operators’ specific desires.

AutoClutch sensitivity can be adjusted on the transmission settings page in the CommandCenter display. Operators can turn off AutoClutch or choose from high, medium, or low sensitivity. Operators can fine-tune AutoClutch by delaying the response time, based on load, travel speed, etcetera. This allows the trailer brakes to be applied before AutoClutch engages.

The AutoClutch sensitivity factory default-setting is set to high, which supports most operations.

AutoClutch sensitivity settings are available in all three modes – auto, custom, and manual.

Efficiency manager

|

| Set speed buttons and set speed adjuster |

Efficiency manager is automatically enabled in full AUTO and custom mode. Efficiency manager can be turned on in manual mode by selecting the set speed one or two on the CommandARM. The set speed adjuster on the top of the single-lever gear selector allows the operator to dial in the desired ground speed to establish set speed one or two in Efficiency Manager.

Efficiency manager allows the transmission to up or down shift and change engine rpm to maintain the set wheel speed. To reach the desired set speed, the throttle must be set to full engine rpm. This allows efficiency manager to shift the transmission and adjust engine speed to maintain the desired wheel speed. For more information on Efficiency Manager refer to the operator’s manual.

e23 operation

Both right-hand reverser and left-hand reverser control options provide full powershifts for on-the-go shifting; no need to stop or clutch when bump shifting or shuttle shifting between forward and reverse.

The single-lever shifter allows for quick and convenient shifting with minimal physical effort.

Shifts are made either by bumping the lever or by holding the lever in a forward or rearward position.

A forward gear between 1F and 13F may be preselected by depressing the clutch pedal and pushing or pulling the shift lever. The transmission will then start in the preselected forward gear when clutch pedal is released.

Eco button

Eco button Display screen

Display screenIn custom mode, eco allows two minimum engine speeds to be set. Operators can turn eco on and off by either pushing the eco button on the side of the throttle or by selecting eco in the transmission settings page of the CommandCenter. For example, operators may choose to turn eco on during transport to utilize a lower minimum engine speed and then turn eco off while operating in the field where a higher minimum engine speed is desired.

Custom settings page

Custom settings page

In the advanced settings page, operators can customize the auto shift engine speed droop as a percentage of the full engine speed. In addition, the load anticipation feature can be enabled for the hitch engagement, hydraulic engagement, or both.

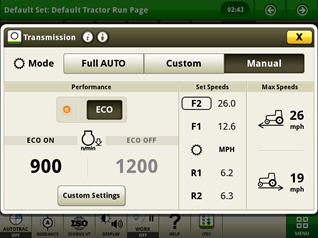

Manual mode page

Manual mode page

Manual mode operates similar to a traditional PowerShift transmission. When shifting, the transmission shifts gears, not set speeds like full AUTO and custom mode. Manual mode also features efficiency manager when the operator engages set speed one or two on the CommandARM, as shown above in illustration.

When operating in manual mode with efficiency manager active, there is the option of turning eco on or eco off. This allows the operator to select two different minimum engine speeds. In the advanced settings page, operators can adjust auto shift engine speed droop and load anticipation, similar to custom mode.

Cornerpost display

Cornerpost display

The cornerpost display shows the commanded gear instantaneously once selected.

| Option code | Description |

| 1493 | e23 Transmission 42 km/h (26 mph) with Efficiency Manager |

| 1494 | e23 Transmission 50 km/h (31 mph) with Efficiency Manager |

| 2701 | Right-hand Reverser Bump-Shift-Type Transmission Controls |

| 2702 | Left-hand Reverser Bump-Shift-Type Transmission Controls |

Rapid shifting

Rapid shifting

When the tractor is working in a light-load condition, for example in transport, the transmission can be shifted rapidly by bumping the shift lever.

To reach transport speeds quickly:

Double shifting

The transmission can skip a gear when operating under load by double bumping the shift lever.

Ground speed matching

When the tractor is slowing down and the clutch pedal is depressed, the transmission will match a gear to the ground speed of the tractor when the clutch is released. Ground speed matching only engages in gears 13F higher.

Setting start-up gears

The transmission defaults to 8F and 3R at start-up. However, these default start-up gears can be adjusted from 1-13F and 1-6R through the CommandCenter. Refer to the operator’s manual for additional information.

|

| Start-up gears in advanced settings |

Releasing the park brake

The e23 transmission utilizes a spring-engaged/hydraulically-disengaged park brake. The park brake control feature prevents accidental park brake engagement when tractor is moving at high speed.

On tractors equipped with air brakes, the park brake automatically activates the air brake system.

CommandView III cab

CommandView III cabThe Standard CommandView III cab offers unsurpassed visibility, operator comfort, control placement, and ride and sound quality.

Features:

ComfortCommand seat

ComfortCommand seatComfortCommand seat improves ride quality and helps to reduce operator fatigue.

Features include:

Fingertip paddle pots

Fingertip paddle pots Encoder wheel

Encoder wheel CommandARM controls

CommandARM controlsJohn Deere 7R and 8R Series Tractors feature the CommandARM with integrated Generation 4 CommandCenter display. The control layout of the CommandARM utilizes a clean and efficient design which groups controls by function and builds upon John Deere’s history of intuitive and ergonomic control placement and operation. The design of the CommandARM allows for a 40 degree right seat swivel and adjustable positioning matching the operator’s preference.

Controls located on the CommandARM include:

John Deere 7R Series Tractors with CommandQuad transmissions feature a left-hand reverser. 8R Series Tractors equipped with 16-speed PST are equipped with right-hand reverser. 7R Series Tractors equipped with e23 PST offer a left- or right-hand reverser. 7R or 8R Series Tractors equipped with AutoPowr™/IVT transmissions are offered with either a left-hand or a right-hand reverser.

The transmission control lever is placed on the left side of the CommandARM closest to the operator for convenient setting and adjustment.

Left-hand CommandQuad/e23 reverser

Left-hand CommandQuad/e23 reverser Right-hand IVT and PST reverser

Right-hand IVT and PST reverser 16-speed PST right-hand reverser

16-speed PST right-hand reverserHydraulic and hitch controls utilize fingertip paddle pots for raise/lower and extend/retract functions. An optional crossgate joystick replaces fingertip paddle pots for control of SCVs and allows for programmable hydraulic functionality according to operator preference. Rear hitch position can also be controlled with the encoder wheel located on the right side of the CommandARM. The encoder wheel allows for finite positioning of the rear 3-point hitch.

Three buttons near the encoder are for hitch set, lock, and return to height. Adjustment knobs for the 3-point hitch are located under the cover for the CommandARM control's storage compartment and allow for adjustment of the rate of drop, hitch height limit, and depth control.

Hitch controls

Hitch controls Optional crossgate joystick

Optional crossgate joystickThrottle

The throttle design incorporates buttons which control FieldCruise speed, foot pedal mode (if equipped), and transmission eco settings.

Throttle

Throttle Foot throttle

Foot throttleTractor function controls

Located just to the right of the throttle is the AutoTrac activation button and four sequence controls for iTEC functions. Behind the iTEC sequence controls, there are buttons which control the activation and deactivation of MFWD and differential lock.

AutoTrac resume and iTEC strip

AutoTrac resume and iTEC stripControls for radio, lights, rotary beacon (if equipped), hazard flashers, and HVAC system are located to the center-right on the CommandARM, along with PTO for both front (if equipped) and rear PTO.

Radio, HVAC, hazard flashers, and PTO controls

Radio, HVAC, hazard flashers, and PTO controlsSeat swivel

The design of the CommandARM allows for up to 40 degrees of right-hand seat swivel.

Seat swivel

Seat swivel Generation 4 CommandCenter

Generation 4 CommandCenterThe Generation 4 CommandCenter features fast adjustment of tractor functions and controls and are integrated into the CommandARM to create a seamless control center. The 4100 CommandCenter features a 178-mm (7-in.) touchscreen display and is standard equipment on 7210R and 7230R models, while the 4600 CommandCenter features a 154-mm (10-in.) touchscreen and is standard equipment on 7250R – 7310R models, as well as all 8R and 8RT models.

The following functions can be adjusted using the CommandCenter display:

7R Series cooling package

7R Series cooling package Pull-style fan and radiator access

Pull-style fan and radiator accessThe 7R Series Tractors feature an increased front area (IFA) cooling system that utilizes a pull-style fan that improves cooling efficiency over an increased surface area that provides better cooling capacity and reduces fan noise during increased power levels or while under heavy loads.

Hood screen area

Hood screen area Engine hood with side shields

Engine hood with side shieldsThe 7R Series Tractors also have an increased screen area on the hood and redesigned side shields to help reduce debris buildup. The new cooling system provides easy, cooler cleanout and service accessibility without sacrifice to turning radius or front hitch and front power take-off (PTO) applications.

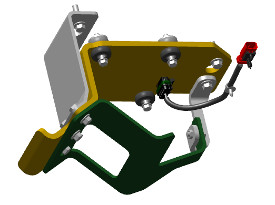

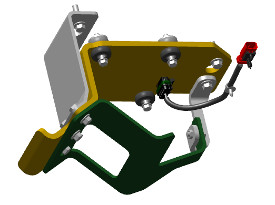

7R Series Tractor with front hitch

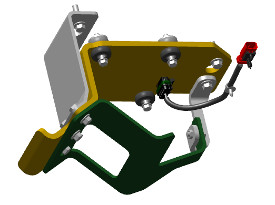

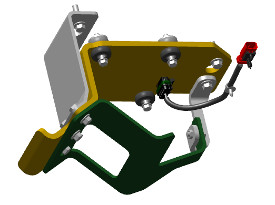

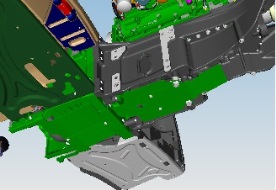

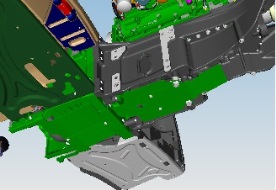

7R Series Tractor with front hitchThe 7R Series Tractors offer two front hitch options to best fit a variety of applications.

Standard (non-ground-engaging) hitch option for applications including, but not limited to:

Premium (ground-engaging) hitch option for applications including, but not limited to:

Premium hitches include a push bar and heavier lift arms:

To ensure adequate hydraulic availability, up to two selective control valves (SCVs) can be included with a front hitch.

Joystick control

Joystick control Paddle pot SCV

Paddle pot SCVTractors equipped with a factory front hitch have the option of selecting a joystick control or paddle pot SCV controls. The joystick control is not compatible with the sixth rear electrohydraulic SCV because of the CommandARM™ controls space required for the front hitch joystick.

Features of John Deere factory-installed front hitches include:

| Standard | Premium |

Lift capacity at ball ends (ISO) | 5200 kg (11,464 lb) | 5200 kg (11,464 lb) |

Lift range | 750 mm (29.5 in.) | 750 mm (29.5 in.) |

Overhang when folded | 55 mm (2.2 in.) | 55 mm (2.2 in.) |

Approach angle (depending on tire and axle setup) | 25.5 - 38.7 degrees | 25.5 - 38.7 degrees |

Reinforcing push bar | Field-installed option | Standard |

Auxiliary valve with front couplers | Optional | Standard |

Category 3N hitch | Standard | Standard |

7-pin connector - for implement lights | Standard | Standard |

9-pin harness and connector (ISO) | Field-installed option | Field-installed option |

Front-mounted remote switch | Standard | Standard |

Hitch damping | Triple-Link Suspension (TLS™) axle, same effect | TLS axle, same effect |

Hydraulic mode select | Single and dual | Single and dual |

Electronic position control | Yes | Yes |

Full ground clearance | Yes | Yes* |

iTEC™ compatible | Yes | Yes |

Power take-off (PTO) compatible | Yes | Yes |

Installed weight (with push bar)** | -- | 455 kg (1003 lb) |

Installed weight (no push bar)** | 345 kg (760 lb) | -- |

*Hitches with a push bar maintain front axle to ground clearance for row-crop applications and can be used with ground-engaging implements, including primary tillage implements and standard blades.

**Equals weight of added hitch components.

The integrated and styled compact hitch design maintains full maneuverability even with the larger front tires. The hitch extends only 55-mm (2.2-in.) ahead of the front support when the arms are folded.

Standard (carrier version) hitches can be converted to a premium (ground-engaging) hitch by ordering and field installing a conversion kit that includes push bar and heavier lift arms.

All factory-installed front hitches are capable of single- and dual-acting hydraulic cylinder modes. This allows the operator the flexibility to choose the correct mode for a variety of front hitch applications. Single acting provides hydraulic force for retracting the front hitch cylinders and allows front implements to follow the contour of the ground or surface. For example, this would be the correct mode for a front-mounted snow blower. Dual acting provides hydraulic force in retracting and extending the front hitch cylinders to provide down force for ground-engaging implements.

Additional hitch features include:

7R position sensing

7R position sensingThe 7R with front hitch comes equipped with position sensing that allows operators the ability to establish an upper height limit set point and lower limit set point through CommandCenter™ display. Position sensing maintains the height of the hitch arms based on the set points.

Position sensing provides the following benefits:

For a 9-pin connector, order kit RE322555. The kit includes all necessary components and allows ISO implement communication.

NOTE: 7R Series Tractors with a factory-installed front hitch do not ship with a front weight support.

Front hitch – Field-installed options:

For more information on ordering a front hitch ready configuration, refer to Attachments, front hitch/power take-off (PTO) ready

For tractors ordered non-hitch or non-hitch ready please contact LaForge® company for front hitch options.

Laforge Systems Inc.

4425-C Treat Blvd. #230

Concord, California 94521

Phone: (925) 827-2010 or 1-800-422-5636

Web site: www.fronthitch.com

LaForge is a trademark of Laforge Corporation.

Front hitch options:

7R with TLS Plus

7R with TLS Plus

The optional TLS Plus is a fully integrated, self-leveling front suspension system available on 7R Series Tractors equipped with the 1300 mechanical front-wheel drive (MFWD) axle. TLS Plus provides exclusive front suspension using a hydro-pneumatic self-leveling system to increase productivity and improve ride dramatically. TLS Plus provides more control over the front suspension of the tractor.

CommandCenter screen

CommandCenter screen

In the Generation 4 CommandCenter™, the operator is able to select maximum pressure to accommodate for the transfer of heavy loads with minimal front axle movement.

TLS Plus increases both transport and field productivity with superior stability, ride, and comfort. Loader operators appreciate the enhanced performance when transporting bales or a full bucket of silage. In the field, the TLS Plus front suspension maintains ground-to-tire contact, enabling more power to the ground.

The TLS Plus front axle is available with or without wet-disc front brakes. While TLS Plus is available on all 7R Series Large-Frame Tractors, it is a requirement for the following:

31-mph/50K CommandQuad™ Eco

31–mph/50K e23™

31–mph/50K infinitely variable transmission (IVT™)

7R with TLS Plus

7R with TLS PlusTwo double-acting-control cylinders act independently or together to dampen shock loads, while supplying a constant down force on the axle for better traction. In addition to the cylinders, a pan-hard rod limits lateral motion while an electronic sensor signals a priority valve to automatically move the control cylinders as needed.

The cast driveline draft member controls fore-aft suspension of the axle. This heavy-duty conical casting encloses the entire driveline and transfers longitudinal forces to the tractor's center of gravity.

1300 axle with TLS Plus

1300 axle with TLS Plus 1300 axle cutaway with TLS Plus

1300 axle cutaway with TLS PlusOperating characteristics:

Automatic differential lock angle adjustment

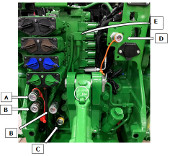

Automatic differential lock angle adjustment CommandARM™ controls with automatic differential lock engaged

CommandARM™ controls with automatic differential lock engaged CommandARM controls with manual differential lock engaged

CommandARM controls with manual differential lock engagedThe differential lock is another feature of the 1300 Series MFWD axle with Triple-Link Suspension (TLS) PLUS, driveline shield, hydraulic on/off differential lock, and wet-disk front brakes. When the rear differential lock is engaged or disengaged, the front differential lock is also engaged or disengaged. This also includes a driveline shield.

If one wheel begins to slip, the differential lock can be engaged on the go and the axles are hydraulically locked together for maximum traction. There are two ways to engage the differential lock feature.

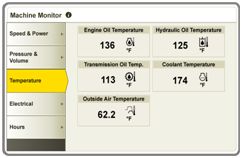

The Generation 4 CommandCenter was designed to provide a consistent user experience by providing full-screen viewing of more run page modules, shortcut keys, and precision agriculture capabilities.

Expect easier set-up, along with increased operator confidence, thanks to a simple, customizable interface. The improved design of the Generation 4 CommandCenter also aids in an optimal operating experience and maximizes uptime.

In order to increase your efficiency, take advantage of the following features offered by the Generation 4 CommandCenter:

Layout manager selection page

Layout manager selection page Layout manager module build

Layout manager module build Machine monitor page

Machine monitor page Work monitor page

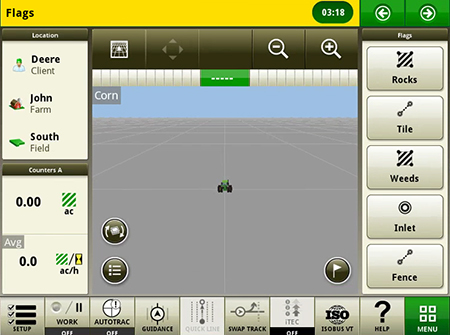

Work monitor page Create flags to mark items in the field

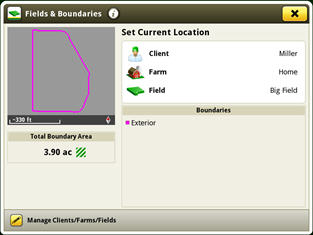

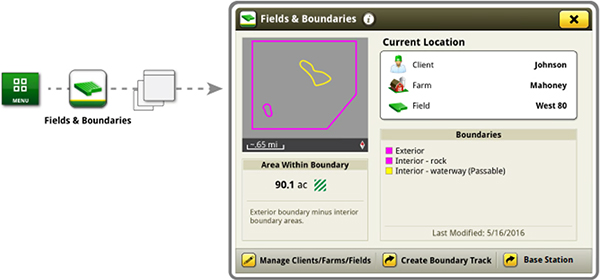

Create flags to mark items in the field Boundary creation from coverage

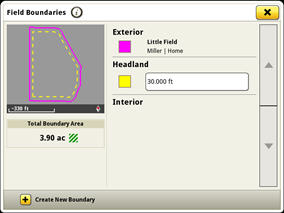

Boundary creation from coverage Headland creation

Headland creation Dual display

Dual displayNOTE: Vehicle applications will always be located on the Gen 4 CommandCenter.

Setup base stations in Fields and Boundaries applications

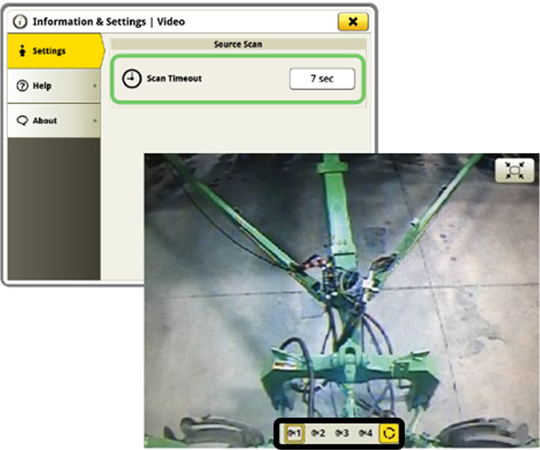

Setup base stations in Fields and Boundaries applications Scan through videos with video looping

Scan through videos with video looping A single manual action; system manages the rest

A single manual action; system manages the rest TBA awards

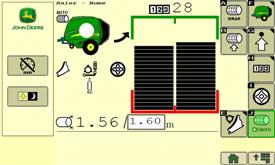

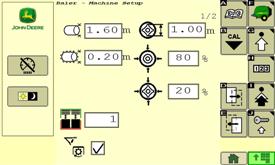

TBA awardsThe optional Tractor-Baler Automation (TBA) makes baling easy. This exclusive system manages most of the baling process and gives the customer the following advantages:

When used with a John Deere ISOBUS tractor, electric selective control valve (E-SCV), and (IVT™) transmission, the system will be able to:

The only action remaining is to forward reverser and manage the steering.

If the John Deere tractor is not equipped with IVT but has E-SCV and ISOBUS, opening and closing can be automated.

A single touch on SCV, brakes, or reverser will disengage the automation. In the same way, automated open/close can be momentarily stopped when unloading in hilly conditions.

Tractor-Implement Automation is an exclusive green on green advantage. This advanced technology option has won awards at SIMA and Agritechnica farm equipment show in Europe, a true cost/value guarantee.

NOTE: to run through fully automated mode, a John Deere Isobus tractor with E-SCV and IVT is required. A baler activation key and a tractor activation key (different) have to be ordered.

Plug in and bale with ISOBUS

Plug in and bale with ISOBUS ISOBUS certified = compatibility guarantee

ISOBUS certified = compatibility guaranteeThe 990 and 960 Balers offer ISOBUS compatibility as base equipment. This standardized communication not only allows the use of John Deere Greenstar2 1800, 2600, or 2630 Displays, but also the use of other ISOBUS conform competitive monitors.

Adapter harnesses for non-ISOBUS tractors are available.

Main page with simple and clear pictograms

Main page with simple and clear pictograms Bale or soft core density adjustments

Bale or soft core density adjustmentsThe Baler interface displays information that is needed. The 900 Series monitors provide all required information:

Adjustments can also be managed from the operators station:

Greenstar2 1800 Display ordered with the baler

Greenstar2 1800 Display ordered with the baler

The 900 Series Balers can be teamed with all ISOBUS certified displays. The Greenstar2 1800 monitor can be ordered with the baler to match traditional baling requirements. When not baling this display can be used for other functions such as guidance and spraying applications when connected to an appropriate receiver and implement.

GreenStar3 2630 fits the most demanding user needs

GreenStar3 2630 fits the most demanding user needs

The 960 and 990 Balers can be ordered without a monitor for customers who already have an ISOBUS display, or for those who search more advanced application (field management). Displays other than John Deere Greenstar2 1800 can be purchased through Ag Management Solutions (AMS) pages.

Compare the specifications of up to 4 models

| Key Specs | 7230r-tractor Current Model |

|---|---|

| Engine description | John Deere PowerTechPSS (B20 Diesel Compatible) 6.8L |

| Engine displacement | 6.8 L 415 cu in. |

| Rated engine power | At 2100 engine rpm: 169 kW 230 hp |

| Rated PTO power (hp SAE) | At 2100 engine rpm: 140 kW 189 hp |

| Transmission type | Standard: John Deere e23™ 42 km/h 26 mph Optional: John Deere 20 Speed CommandQuad Transmission 40 K John Deere 20 Speed CommandQuad Transmission 50 K 31 mph John Deere e23™ Transmission 50 K John Deere Infinitely Variable Transmission (IVT) 0.050-42 km/h (0.030-26 mph) John Deere Infinitely Variable Transmission (IVT) 0.050-50 km/h (0.030- 31 mph) |

| Hydraulic pump rated output | Standard: 63 cc: 162 L/min 43 gpm Optional: 85 cc: 222.3 L/min 59 gpm |

| Rear hitch category (SAE designation) | Standard: Category 3/3N with Quik-Coupler Optional: Category 3/3N with Hook Ends |

| Base machine weight | 10,512 kg 23,175 lb |

| Maximum PTO power | |

| Maximum engine power | |

| Engine specifications | |

| Description | John Deere PowerTechPSS (B20 Diesel Compatible) 6.8L |

| Engine type | Diesel, in-line, 6-cylinder, wet-sleeve cylinder liners with 4 valves-in-head |

| Engine family | JJDXL06.8309 |

| Rated speed | 2100 rpm |

| Aspiration | Dual turbochargers, variable geometry turbo with fixed geometry turbo in series |

| Cylinders liners | |

| Emission level | Final Tier 4 |

| After treatment type | DOC/DPF |

| Displacement | 6.8 L 415 cu in. |

| Engine performance | |

| Rated power | At 2100 engine rpm: 169 kW 230 hp |

| Rated PTO power (hp SAE) | At 2100 engine rpm: 140 kW 189 hp |

| Power boost | 22 kW 30 hp |

| Engine peak torque | At 1600 rpm: 1077 Nm 794 lb-ft |

| PTO torque rise | 40 percent |

| Intelligent Power Management (available in transport and/or mobile PTO applications) | |

| Maximum PTO power | |

| Maximum engine power | |

| Transmission | |

| Type | Standard: John Deere e23™ 42 km/h 26 mph Optional: John Deere 20 Speed CommandQuad Transmission 40 K John Deere 20 Speed CommandQuad Transmission 50 K 31 mph John Deere e23™ Transmission 50 K John Deere Infinitely Variable Transmission (IVT) 0.050-42 km/h (0.030-26 mph) John Deere Infinitely Variable Transmission (IVT) 0.050-50 km/h (0.030- 31 mph) |

| Reverser | |

| Clutch; wet/dry | |

| Creeper | |

| Hydraulic system | |

| Type | Closed-center, pressure/flow compensated |

| Pump rated output | Standard: 63 cc: 162 L/min 43 gpm Optional: 85 cc: 222.3 L/min 59 gpm |

| Available flow at a single rear SCV | 132 L/min 35 gpm |

| Available flow at front SCVs | 126 L/min 33 gpm |

| Number of rear selective control valves (SCVs) | Standard: 4 SCVs Optional: 1/2 in. ISO Couplers: 3-6 0.75 in. and 0.5 in. ISO couplers: 5 (SCV 1: 0.75 in couplers, SCV 2-5: 0.5 in coupler) |

| Number of mid selective control valves (SCVs) | |

| Number of front selective control valves (SCVs) | 1 with front hitch |

| Joystick SCV control | |

| SCV control | Electronic |

| Rear hitch | |

| Hitch draft control load sense type | |

| Remote control valves available | |

| Hitch category (SAE designation) | Standard: Category 3/3N with Quik-Coupler Optional: Category 3/3N with Hook Ends |

| Maximum lift capacity behind lift points | Standard (Category 3): 5443 kg 12,000 lb Optional (Category 3N): 6894 kg 15,200 lb Standard (Category 3 with Hook Ends): 5443 kg Optional (Category 3 with Hook Ends): 6894 kg 15,000 lb |

| Sensing type | Electrohydraulic |

| Rear axle differential lock | |

| Lift capacity at standard frame | |

| Drawbar | |

| Drawbar category | Standard: Category 3 Optional: Category 3 with heavy duty support |

| Maximum vertical load | Standard: Category 3: 1837 kg 4050 lb Optional: Category 3 with heavy duty support: 4536 kg 10,000 lb |

| Rear power take-off (PTO) | |

| Type | Independent Standard: 44.45 mm (1.75 in.) 20-spline, 1,000 rpm Optional: 44.45 mm (1.75 in.), 20-spline, 1,000 rpm capable of 35 mm (1.375 in.) 540/1000 rpm 44.45 mm (1.75 in.) 20-spline, 1,000 rpm with 1.375 in. 540E/1000/1000E rpm gearcase 44.45 mm (1.75 in.) 20-spline, 1,000 rpm with 1.375 in. 540/540E/1000 rpm gearcase |

| Engine rpm (at rated PTO speeds) | 540/1000 PTO rpm at 1950 engine rpm 540E/1000E PTO rpm at 1750 engine rpm |

| PTO actuation | |

| Ground speed PTO option availability | |

| Multispeed PTO option availability | |

| Front hitch | |

| Category | Category 3N, ground engaging |

| Electric power | 7-pin connector |

| Standard lift capacity | 5,200 kg 11,464 lb |

| Front power take-off (PTO) | Available Optional: 44.45 mm (1.75 in.), 20 spline, 1,000 rpm, counter-clockwise rotation (when facing PTO) 35 mm (1.375 in.) 21 spline, 1,000 rpm, counter-clockwise rotation (when facing PTO) 35 mm (1.375 in.) 6 spline, 1,000 rpm, counter-clockwise rotation (when facing PTO)** |

| PTO speed | 1,000 PTO rpm at 1940 engine rpm |

| Rear axle | |

| Type | Standard: Rack-and-pinion or flange axles Optional: Diameter: 100 x 3010 mm 3.94 x 118.5 in. Diameter: 100 x 2808 mm 3.94 x 110.5 in. 4.33 x 110.5 in. Diameter: 100 x 2550 mm 3.94 x 100.4 in. 335 mm (13.2 in.) Flanged Axle |

| Final drive type | Inboard planetary three pinion |

| Differential controls | |

| Axle type | |

| Brakes, type and control | |

| Rear differential lock | Full-locking electrohydraulic |

| Load rating | |

| Front axle | |

| Type | Standard: 1300 Series MFWD: tread range 1524 to 2235 mm 60 - 88 in. Optional: TLS: Tread range 1524 to 2235 mm TLS with front brakes, available with 40 kph, standard with 50 kph |

| Front axle differential lock | 1300 Series MFWD: Limited Slip TLS: Limited Slip TLS with front brakes: Full-locking electrohydraulic (actuated at same time as rear diff lock) |

| Load rating | |

| Tires | |

| Front | RCI Group 42/43 |

| Rear | RCI Group 47/48 |

| Wheel tread range | |

| Turning radius with brakes | 380/85R34 group 42 tires at 60 in. spacing 1300: 7 m 23 ft 600/70R30 group 43 tires at 74.1 in. spacing TLS: 6.7 m 22 ft |

| Turning radius without brakes | |

| Steering | |

| Type | Standard: Hydrostatic power Optional: ActiveCommand™ Steering with electric pump back-up |

| Electrical system | |

| Alternator size | Standard: 200 amp Optional: 240 amp |

| Battery options | 12 V |

| Total cold cranking amps | With 2-925 CCA group 31 batteries: 1850 CCA |

| Type of bulb in beacon (Halogen, Zenon, LED) | |

| Type of bulb in headlight (Halogen, Zenon, LED) | |

| Working lights | |

| dB(A) rating for backup alarm | |

| Operator station | |

| Rollover protective structure, OOS | |

| Seat | Standard: ComfortCommand™ Optional: ActiveSeat™ |

| Cab suspension | Optional: Adaptive Hydropneumatic Cab Suspension Plus (Adaptive HCS Plus) |

| Instructional seat | Standard |

| Display | 10-in. CommandCenter Display with 4600 processor |

| Radio | Standard: AM/FM stereo with weatherband, remote controls, auxiliary input jack, four speakers and external antenna Optional; Premium: AM/FM stereo with premium tuner, weatherband, remote controls, USB port and auxiliary input jack , BlueTooth capable including microphone, four speakers, subwoofer, and external antenna |

| Inner cab volume | 3.597 m3 127 cu ft |

| dB(A) rating | |

| Cab glass area | 6.52 m2 70.18 sq ft |

| Front visibility | |

| Safety glass rating | |

| Dimensions | |

| Wheelbase | 2925 mm 115.2 in. |

| Overall length | 5520 mm 217 in. |

| Drawbar clearance | Group 47 rear tires: 360 mm 14.2 in. Group 48 rear tires: 415 mm 16.3 in. |

| Front axle center | |

| Approximate shipping weight, Open;Cab | |

| Overall height | |

| Weight | |

| Base machine weight | 10,512 kg 23,175 lb |

| Maximum ballast level | SAE PTO hp: 65.8 kg 145--- lb |

| Maximum permissible weight | |

| Capacities | |

| Crankcase oil volume | 26 L 27.4 U.S. gal. |

| Fuel tank | CQT (G47/48): 503 L 133 U.S. gal. e23 (G47/48): 465 L 123 U.S. gal. IVT (G47/48): 520 L 137 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | 23 L 6 U.S. gal. |

| Cooling system | 39.5 L 41.75 qt |

| Transmission-hydraulic system | 160 L 42.3 U.S. gal. |

| Serviceability | |

| Interval for engine oil change | 500 hours |

| Interval for hydraulic/transmission oil change | 1,500 hours |

| Interval for engine coolant change | 6,000 hours |

| Loaders | |

| Loader | H480 |

| Lift capacity at full height | 2411 kg 5315 lb |

| Maximum lift height | 4704 mm 185.2 in. |

| Precision AG | |

| Guidance | AutoTrac Ready |

| Telematic | JDLink |

| Remote diagnostics | ServiceADVISOR remote: available with JDLink™ hardware and activations Remote Display Access: available with JDLink™ hardware and activations |

| Miscellaneous | |

| Country of manufacture | USA |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Tracks | |

| Drive type | |

| Midrollers | |

| Track width | |

| Tread spacing |

This product is similar to the protective film used on hand-held touchscreen electronics and can reduce screen damage from regular use. It includes all necessary instructions and tools to install the transparent film over a touchscreen display.

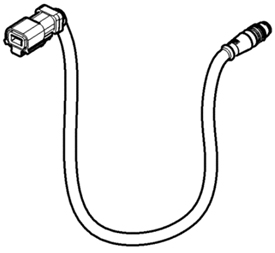

GreenStar 2 vehicle connector

GreenStar 2 vehicle connectorThe rotary beacon light is installed to meet requirements in commercial or governmental applications. The rotating, high-intensity light rests securely within an amber-colored safety lens. Both the light and lens are replaceable if damaged.

The rotary beacon light features a fully adjustable, double-clamp design that provides a more rigid vertical support stem.

The rotary beacon light is installed to meet requirements in commercial or governmental applications. The rotating, high-intensity light rests securely within an amber-colored safety lens. Both the light and lens are replaceable if damaged.

The rotary beacon light features a fully adjustable, double-clamp design that provides a more rigid vertical support stem.

The left-hand step mud guard is intended for use with the full-coverage rear fender. The left-hand step mud guard is provided with G49 rear tires.

Right-hand window wiper

Right-hand window wiperOptional right-hand window wiper with washer fluid is available on standard and premium cabs. This option allows the operator to clean the window in dusty conditions from the comfort of the cab. The windshield wiper fluid tank is located on the operator platform near the front of the cab.

Block distractions out of the left side window of select tractor and sprayer cabs. The left-side sun shade bracket allows producers to mount their choice of two different sized sun shades to the cab door. The shade system design allows operators to block light and heat from the sun while not obstructing the cab entrance and exit access. The bracket kit is compatible with existing sun shades for a matched look in the cab with quality and features users are already comfortable with.

Bracket shown with large sun shade retracted on 8RT

Bracket shown with large sun shade retracted on 8RT  Sun shade 30 percent open on 8RT

Sun shade 30 percent open on 8RT Sun shade 95 percent open on 8RT

Sun shade 95 percent open on 8RT Bracket shown with large sun shade at 95 percent open on 8RT with door open

Bracket shown with large sun shade at 95 percent open on 8RT with door open

This optional cross-gate joystick replaces fingertip paddle pots for control of selective control valves (SCVs) and allows for programmable hydraulic functionality according to operator preference.

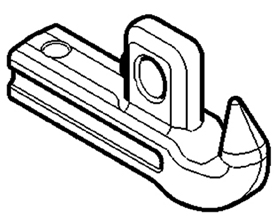

Cat. 3 drawbar with clevis with pin

Cat. 3 drawbar with clevis with pin Cat. 3 drawbar with clevis with pin

Cat. 3 drawbar with clevis with pinHigh vertical load drawbar improves tractor versatility by being compatible with implements with high hitch vertical loads.

This Category 3 drawbar option includes a heavy-duty drawbar support with maximum drawbar static vertical load at 10,000 lb and can be adjusted to 10-, 14-, and 16-in. lengths required by PTO implements. Drawbar pin size is 1.5 in.

Applications:

Medium- to heavy-sized 3-point-hitch implements, such as row-crop cultivators, and typical- to heavy-sized drawn field implements such as a field cultivator, chisel plow, or loaded grain carts.

9-pin electrical connector

9-pin electrical connectorThe 9-pin electrical connector is required to allow TouchSet depth control to be used with implements with this feature. The harness provides a position input to the tractor selective control valve unit enabling the TouchSet system.

This feature allows the operator to adjust height and depth of remote lift cylinders by using the TouchSet controls in the cab.

Battery disconnect installed

Battery disconnect installedAvailable as either a factory- or field-installed attachment, the battery disconnect switch is used to disconnect the batteries in preparation for 20-day to 90-day storage periods. The switch cuts the power to the entire tractor to aid in maintaining battery life.

An indicator light allows for safe and proper disconnect. The light will flash until it is safe to disconnect. This allows the diesel exhaust fluid (DEF) tank and lines to purge. (Final Tier 4 has an indicator light and Interim Tier 4 has no indicator light.)

Cummins is a trademark of Cummins Incorporated.

All model years of R4030, R4038, R4044, R4045, and R4060 Sprayers can be upgraded to include ExactApply intelligent nozzle control. The ExactApply performance upgrade kits are compatible with steel and carbon fiber booms. Additionally, the sprayer needs stainless-steel plumbing and nozzle spacing of 38 cm or 51 cm (15 in. or 20 in.).

ExactApply on 4640 Universal Display

ExactApply on 4640 Universal DisplayExactApply performance upgrade kits are compatible with the GreenStar™ 3 2630 Display, the 4600 CommandCenter™ Display, and the 4640 Universal Display.

| Boom width | Boom type | Time |

| 27.4 m (90 ft) | Steel | 20 hours |

| 30.5 m (100 ft) | Steel | 22 hours |

| 36.6 m (120 ft) | Steel | 24 hours |

| 36.6 m (120 ft) | Carbon fiber | 19 hours |

| 40.2 m (132 ft) | Carbon fiber | 21 hours |

Four part numbers need to be ordered to complete an ExactApply performance upgrade kit. Kits are customized based on the sprayer’s chassis, boom, alternator, and display.

Step 1: Select a chassis kit.

| Model | Configuration | Kit |

| R4030 | Poly tank | BKK10805 |

| Stainless-steel tank | BKK10806 | |

R4038 R4044 | Stainless-steel tank | BKK10806 |

R4045 R4060 | Stainless-steel tank | BKK10806 |

Step 2: Select a boom kit.

| Model | Configuration | Kit |

R4030 | 27.4-m (90-ft) steel boom with 38-cm (15-in.) spacing | BKK10807 |

| 27.4-m (90-ft) steel boom with 51-cm (20-in.) spacing | BKK10808 | |

| 30.5-m (100-ft) steel boom with 38-cm (15-in.) spacing | BKK10809 | |

| 30.5-m (100-ft) steel boom with 51-cm (20-in.) spacing | BKK10810 | |

| 36.6-m (120-ft) steel boom with 38-cm (15-in.) spacing | BKK10811 | |

| 36.6-m (120-ft) steel boom with 51-cm (20-in.) spacing | BKK10812 | |

| 36.6-m (120-ft) carbon fiber boom with 38-cm (15-in.) spacing | BKK11125 | |

| 36.6-m (120-ft) carbon fiber boom with 51-cm (20-in.) spacing | BKK11124 | |

| 40.2-m (132-ft) carbon fiber boom with 38-cm (15-in.) spacing | BKK11123 | |

| 40.2-m (132-ft) carbon fiber boom with 51-cm (20-in.) spacing | BKK11122 |

Step 3: Select an alternator kit.

| Model | Configuration | Kit |

| R4030 | Alternator for 6.8 L (415-cu in.) engine | AKK18421 |

R4038 | Alternator for 9.0 L (549-cu in.) Final Tier 4 (FT4) engine | RE550906 |

Step 4: Select a display kit.

NOTE: This kit includes the software and operator's manual. An additional display does not need to be purchased.

| Model | Configuration | Kit |

R4030 | Software and manual kit, GreenStar 3 2630 Display and 4640 Universal Display – US | BKK10813 |

| Software and manual kit, GreenStar 3 2630 Display and 4640 Universal Display – Canada | BKK10814 | |

| Software and manual kit, Gen 4 display – US | BKK10815 | |

| Software and manual kit, Gen 4 display – Canada | BKK10816 |

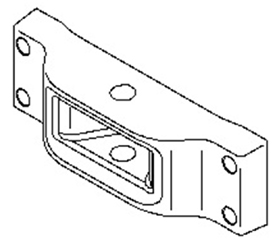

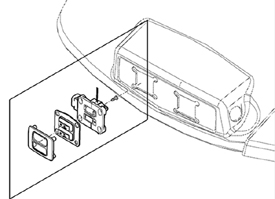

ISO 11783 location in R-Series Tractor cab

ISO 11783 location in R-Series Tractor cab RE322780 ISO cab implement CAN bus adapter

RE322780 ISO cab implement CAN bus adapterThe ISO cab implement controller area network (CAN) bus adapter is available to connect any ISO compliant implement or device to an 8R, 8RT, 9R, 9RT, 9RX (including Scraper Special) Series Tractor. These connectors are commonly used for planter frame control boxes.

Refer to the operator's manual, sections 16 (CommandCenter™) and 25 (Operator Station), for additional information on ISO implements.

NOTE: If the harness is not in use, unplug it from the ISO 11783 location or plug the 4-pin connectors together on the harness. If neither of these are done, implement CAN communication errors will occur.

Implement switch

Implement switch The implement switch indicates to the CommandCenter™ when the implement is raised or lowered, to provide accurate data collection when using a performance monitor.

Dual-beam radar emission horns

Dual-beam radar emission horns  Dual-beam radar (tracks tractor shown)

Dual-beam radar (tracks tractor shown) Shield for dual radar beam

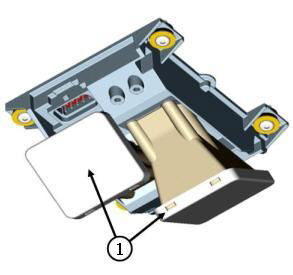

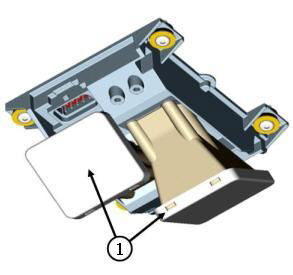

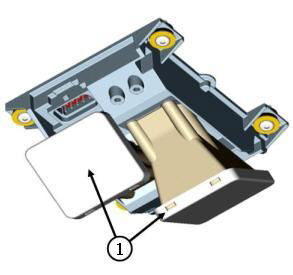

Shield for dual radar beamIn today’s agricultural environment, accuracy and precision are more important than ever. For something as basic as ground speed, operators need key information for precise control of various implements and the tractor. To support these needs, tractors can be ordered with a dual-beam radar unit as a factory- or field-installed option.

There are several key features that have changed from previous designs.

First, there are two horns for exit of the radio beam. This dual-beam design assures a powerful and accurate signal that will cut through interference that at times makes single-beam units inaccurate. (See 1 in the image above for beam locations.) Dual-beam output makes radar less susceptible to hard surface or tall/wavy grass interference.

Accuracy is aided by a heavy-gauge mounting bracket and rubber isolators that reduce chances that vibration can affect the radio signal.

Dual-beam radar has a fast update rate. When the tractor comes to a stop, accelerates, or varies speed, the indicated ground speed on the tractor display will closely match the actual ground speed. This is important for implements that use radar speed to control operation such as planters, seeders, fertilizer applicators, and sprayers.

In addition, the dual-beam radar does not require calibration to assure accuracy. Its self-calibrating ability is sure to save setup time by elimination of a special procedure that was required in the past.

The radar true ground speed sensor activates the following CommandCenterTM display or performance monitor readouts:

Radar usage improves the accuracy of the following CommandCenter or performance monitor functions:

Dual-beam units are compatible with controller area network (CAN) bus and International Organization for Standardization (ISO) bus electrical systems.

Dual-beam radar emission horns

Dual-beam radar emission horns  Dual-beam radar (tracks tractor shown)

Dual-beam radar (tracks tractor shown) Shield for dual radar beam

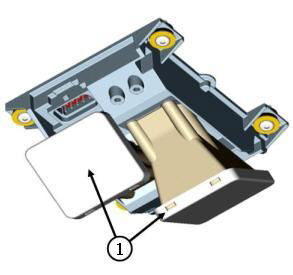

Shield for dual radar beamIn today’s agricultural environment, accuracy and precision are more important than ever. For something as basic as ground speed, operators need key information for precise control of various implements and the tractor. To support these needs, tractors can be ordered with a dual-beam radar unit as a factory- or field-installed option.

There are several key features that have changed from previous designs.

First, there are two horns for exit of the radio beam. This dual-beam design assures a powerful and accurate signal that will cut through interference that at times makes single-beam units inaccurate. (See 1 in the image above for beam locations.) Dual-beam output makes radar less susceptible to hard surface or tall/wavy grass interference.

Accuracy is aided by a heavy-gauge mounting bracket and rubber isolators that reduce chances that vibration can affect the radio signal.

Dual-beam radar has a fast update rate. When the tractor comes to a stop, accelerates, or varies speed, the indicated ground speed on the tractor display will closely match the actual ground speed. This is important for implements that use radar speed to control operation such as planters, seeders, fertilizer applicators, and sprayers.

In addition, the dual-beam radar does not require calibration to assure accuracy. Its self-calibrating ability is sure to save setup time by elimination of a special procedure that was required in the past.

The radar true ground speed sensor activates the following CommandCenterTM display or performance monitor readouts:

Radar usage improves the accuracy of the following CommandCenter or performance monitor functions:

Dual-beam units are compatible with controller area network (CAN) bus and International Organization for Standardization (ISO) bus electrical systems.

Dual-beam radar emission horns

Dual-beam radar emission horns  Dual-beam radar (tracks tractor shown)

Dual-beam radar (tracks tractor shown) Shield for dual radar beam

Shield for dual radar beamIn today’s agricultural environment, accuracy and precision are more important than ever. For something as basic as ground speed, operators need key information for precise control of various implements and the tractor. To support these needs, tractors can be ordered with a dual-beam radar unit as a factory- or field-installed option.

There are several key features that have changed from previous designs.

First, there are two horns for exit of the radio beam. This dual-beam design assures a powerful and accurate signal that will cut through interference that at times makes single-beam units inaccurate. (See 1 in the image above for beam locations.) Dual-beam output makes radar less susceptible to hard surface or tall/wavy grass interference.

Accuracy is aided by a heavy-gauge mounting bracket and rubber isolators that reduce chances that vibration can affect the radio signal.

Dual-beam radar has a fast update rate. When the tractor comes to a stop, accelerates, or varies speed, the indicated ground speed on the tractor display will closely match the actual ground speed. This is important for implements that use radar speed to control operation such as planters, seeders, fertilizer applicators, and sprayers.

In addition, the dual-beam radar does not require calibration to assure accuracy. Its self-calibrating ability is sure to save setup time by elimination of a special procedure that was required in the past.

The radar true ground speed sensor activates the following CommandCenterTM display or performance monitor readouts:

Radar usage improves the accuracy of the following CommandCenter or performance monitor functions:

Dual-beam units are compatible with controller area network (CAN) bus and International Organization for Standardization (ISO) bus electrical systems.

Dual-beam radar emission horns

Dual-beam radar emission horns  Dual-beam radar (tracks tractor shown)

Dual-beam radar (tracks tractor shown) Shield for dual radar beam

Shield for dual radar beamIn today’s agricultural environment, accuracy and precision are more important than ever. For something as basic as ground speed, operators need key information for precise control of various implements and the tractor. To support these needs, tractors can be ordered with a dual-beam radar unit as a factory- or field-installed option.

There are several key features that have changed from previous designs.

First, there are two horns for exit of the radio beam. This dual-beam design assures a powerful and accurate signal that will cut through interference that at times makes single-beam units inaccurate. (See 1 in the image above for beam locations.) Dual-beam output makes radar less susceptible to hard surface or tall/wavy grass interference.

Accuracy is aided by a heavy-gauge mounting bracket and rubber isolators that reduce chances that vibration can affect the radio signal.

Dual-beam radar has a fast update rate. When the tractor comes to a stop, accelerates, or varies speed, the indicated ground speed on the tractor display will closely match the actual ground speed. This is important for implements that use radar speed to control operation such as planters, seeders, fertilizer applicators, and sprayers.

In addition, the dual-beam radar does not require calibration to assure accuracy. Its self-calibrating ability is sure to save setup time by elimination of a special procedure that was required in the past.

The radar true ground speed sensor activates the following CommandCenterTM display or performance monitor readouts:

Radar usage improves the accuracy of the following CommandCenter or performance monitor functions:

Dual-beam units are compatible with controller area network (CAN) bus and International Organization for Standardization (ISO) bus electrical systems.

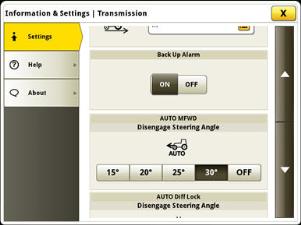

Backup alarm on an 8R Series Tractor

Backup alarm on an 8R Series Tractor Transmission backup alarm kit for 8030 Series

Transmission backup alarm kit for 8030 SeriesTo better accommodate governmental or commercial sales, a back-up alarm is available as a factory- or field-installed attachment on select models. An alarm sounds whenever the transmission is placed in reverse. The alarm provides a high level of warning that the tractor is changing direction.

A backup alarm is base equipment on Scraper Special Series Tractors.

NOTE: IPM is only available for Tier 3/Stage IIIA, Interim Tier 4/Stage IIIB, Final Tier 4/Stage IV engines, and not for Stage II engines.

This feature is for many typical farming operations that use the rear power take-off (PTO) in high-power applications or the tractor as a transport vehicle. Operators who are looking for more power in non-stationary PTO and transport applications will be interested in the IPM feature.

In high rear PTO power applications such as forage harvesters, rototillers, and beet or potato harvesting equipment or where heavy trailers, carts, or implements are moved to and from various locations, this feature provides significant additional capabilities. The solution improves productivity with more consistent ground speeds, quicker acceleration, and the ability to better hold desired transport speeds.

This two-in-one tractor solution successfully operates in power-intensive PTO and transport applications at reasonable low fuel consumption without being disadvantaged by the higher weight, the bigger proportions, and the extra costs of the next higher horsepower model.

This feature is available as a factory- or field-installed option.

8R Tractor in transport

8R Tractor in transport

Rear PTO field applications

Transport applications

This is not intended to be an inclusive list of all applications but shows the wide range of uses for additional engine horsepower.

IPM provides engine power increase in levels proportional to the size of the tractor. IPM provides a controlled power boost of up to 26 kW (35 engine hp) to tractor under the following operating conditions:

Power increase is not provided under draft applications or non-loaded rear PTO applications. Power increase is only provided when required.

There are specific operating parameters when IPM functions to boost engine power. It is the "intelligent" part of the system that provides seamless operation while adjusting the engine horsepower depending on how the tractor is being used. For engine horsepower boost activation, the tractor must already be running an application that is using the full power capability of the tractor.

PTO activation

Power must be sensed going through the PTO drive clutch by the tractor's electronic systems. The tractor must be moving at least 0.5 km/h (0.3 mph) and PTO consuming moderate power before power boost engages. The speeds shown above, assume lowest possible gear or speed setting and the engine running at 2100 rpm.

NOTE: If the tractor is equipped with a front PTO, additional IPM power will transfer through the front PTO. However, IPM activation is only sensed through the rear PTO. Adequate load must be sensed on the rear PTO in order for IPM to activate.

Transport activation

When in transport applications, power transition is smooth. The engine will respond seamlessly as load changes, such as when going up and down hills. Additional power is available at a useful working speed with minor differences between tractor models and transmissions.

The minimum ground speed is where additional power will begin to be applied, assuming the engine is already fully loaded. Ramp up to full additional power occurs as speed continues to increase. Full additional power occurs within a 3 mph (5 km/h) band.

Transport during acceleration: power boost occurs in steps through the range from 23 km/h – 28 km/h (14.3 mph – 17.4 mph).

Transport during deceleration: power boost ramps down in equal steps in the range from 23 km/h – 18 km/h (14.3 mph – 11.2 mph).

Some operators will run the tractor at full loads and/or run transmissions in auto mode in transport. This means that the engine most likely will not be operating at rated rpm. As the engine is loaded, it will eventually drop off of rated rpm and use the power bulge as rpm slows. This is the way every John Deere PowerTech™ Plus engine operates when it is loaded to maximum power and torque.

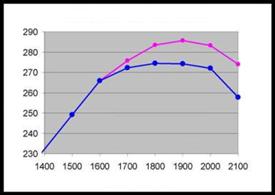

Usable rpm range of operation (8345R shown)

Usable rpm range of operation (8345R shown)

IPM (shown in purple in chart above versus standard power shown in blue) provides additional engine horsepower from rated engine speed down to approximately 1600 rpm (shown on the x-axis in image above, with power kilowatt shown in the y-axis), which is peak engine torque.

Horsepower levels are increased above base equipment power bulge values.

If the PTO is engaged and the engine rpm stays near rated speed of 2100 rpm, the full additional power potential for the tractor model will be available for use to handle additional load from the implement or changing terrain.

If the PTO is not in use and in transport operation, and the rpm has dropped off of rated speed, usable additional power boost of IPM will taper off as rpm decreases. The chart above (with 8345R Tractor power curves) shows the relationship of how much additional usable horsepower is available in the operating range. All tractors operate in a similar manner with this feature.

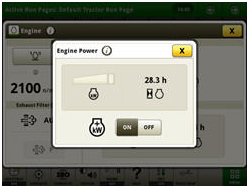

Engine power display

Engine power display

All tractors have the power meter display function as base equipment. The operator can observe when full capabilities of the tractor are being utilized. This function graphically displays power utilization up to rated horsepower and power bulge.

The power meter can be found in the CommandCenter™ display. If the engine is off or has minimal load, the power meter will not fill in. The meter is similar in concept to a cellular phone's signal-strength meter. As the power increases, it will fill in bars in an icon. The display will also show the level of additional power being used. The long section represents up to the rated power. The smaller section represents power bulge and is an indicator of additional power available with IPM.

Via the CommandCenter, there is also the ability to enable or disable the function. The operator's manual provides simple details about navigating the engine screen.

IPM is automatically enabled each time the tractor is started.

IPM has been thoroughly tested by John Deere engineers to be compatible with the base tractor equipment with no impact to reliability. John Deere provides IPM as opposed to unapproved aftermarket devices that boost power without regard to engine, transmission, axles, and drawbar, or hitch capability.

This feature provides optimal utilization of tractor components. For example, with PTO operation, power goes through axles to move the tractor along the ground and turn the PTO shaft and implement. Adding power to both of these systems does not overload either one individually. At transport speeds, drive train torque load decreases significantly from levels seen at low field speeds. Adding power at transport does not overload transmissions or axles.

Aftermarket devices are not selective when power increases are available. Great amounts of power increase are promised with these devices. Large power changes are not compatible with base tractor equipment. To note, base tractor equipment changes as power increases. Larger parts, like hitches, drawbars, tire size, drive train components, axle diameters, and engine calibrations for emission performance and cooling, ensure durability of the total vehicle as power increases. Operating outside of the design capabilities of the tractor base equipment will have an impact on durability and reliability.

Full-coverage fenders

Full-coverage fenders Full-coverage fenders kit for 8030 Series

Full-coverage fenders kit for 8030 SeriesRear fenders are designed to provide optimum mud control by increasing the coverage of the rear tires in all directions. Two rear fender extension options are offered to provide overall width coverage of 2.55 m (100 in.) or 2.75 m (108 in.).

Most importantly, the fender increases the coverage over the rear of the tire, decreasing the amount of mud or debris buildup on the cab's windows, selective control valve (SCV) stack, hitch, and drawbar.

Rear fenders are available as factory-installed or as a field-installed attachment.

Full-coverage fenders

Full-coverage fenders Full-coverage fenders kit for 8030 Series

Full-coverage fenders kit for 8030 SeriesRear fenders are designed to provide optimum mud control by increasing the coverage of the rear tires in all directions. Two rear fender extension options are offered to provide overall width coverage of 2.55 m (100 in.) or 2.75 m (108 in.).

Most importantly, the fender increases the coverage over the rear of the tire, decreasing the amount of mud or debris buildup on the cab's windows, selective control valve (SCV) stack, hitch, and drawbar.

Rear fenders are available as factory-installed or as a field-installed attachment.

This kit includes the deluxe, pivoting, full-coverage, front fender mounting structure for tractors with a mechanical front-wheel drive (MFWD).

-Protection from mud, stones, and debris when using wide front tires

-Same turning angle as tractors without front fenders.

Producers must also order black plastic fenders (R338473 x2).

Recommended for use with Group 43 or 44 front tires, 600 mm (11.8 in.) or wider.

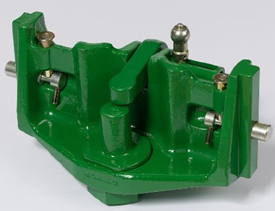

Heavy-duty front hitch

Heavy-duty front hitchThose who want more productivity out of the 7R Series Tractors with a carrier-version front hitch now have the ability to add tillage and other ground-engaging implements with the front-hitch conversion kit. The heavy-duty front hitch is recommended for the most demanding applications. It is designed for extreme stress from pushing hard on tillage implements, very wide implements, severe shock loads, or other heavy-duty applications. Premium hitches are also well suited for mounting three-point blades.

Field-installed kit RE326580 provides a set of heavy-duty lower hitch links, a push bar, and push bar mounting bracket. This hitch is suitable for use under normal conditions including primary tillage equipment or lifting heavy implements. The ground-engaging version is designed for full clearance and does not limit the turning radius at any tread width setting.

The tractor frame includes the mounting points for the push bar, making field conversion possible. Link conversion is possible by removing two pins for each link. Install the push bar with four cap screws in the front, four in the mid-chassis, and tighten two large jam nuts where the push bar attaches to the push bar bracket. There are no ground clearance trade-offs with the addition of the push bar and heavy-duty links. Both versions of the front hitch are entirely compatible with the FPTO (front power take-off).

The conversion kit to ground-engaging front hitch adds 117 kg (260 lb) of additional weight to the tractor.

7R front hitch ready with front weight support

7R front hitch ready with front weight support  7R front hitch ready frame/hydraulic lines

7R front hitch ready frame/hydraulic lines The front hitch/PTO ready option is ideal for any 7R Series Tractor that may be used for future applications requiring a front hitch or PTO. This option is also beneficial for increased resale value as it provides flexibility for future owners.

This option includes a front casting that accommodates, but does not include a front hitch and front PTO.

In-cab controls for front PTO and front hitch have to be ordered through Parts when ordering the front PTO and front hitch field-installed options.

Front hitch ready tractors are not shipped with standard front weight support. A front weight support that bolts to the tractor can be ordered as a factory- or field-installed option (RE326583). The weight support is compatible with suitcase weights (up to 24) and with the 900-kg or 1150-kg (1984-lb or 2535-lb) monster pick-up (monster) weights.

Front weight support is not compatible with front hitch and must be removed before a hitch can be installed.

The sixth rear electrohydraulic SCV is not compatible with front hitch options because of the mid-mount hydraulics for front hitch.

Field-installed hitch options for front hitch/PTO ready tractors:

7R front hitch ready with front weight support

7R front hitch ready with front weight support  7R front hitch ready frame/hydraulic lines

7R front hitch ready frame/hydraulic lines The front hitch/PTO ready option is ideal for any 7R Series Tractor that may be used for future applications requiring a front hitch or PTO. This option is also beneficial for increased resale value as it provides flexibility for future owners.

This option includes a front casting that accommodates, but does not include a front hitch and front PTO.

In-cab controls for front PTO and front hitch have to be ordered through Parts when ordering the front PTO and front hitch field-installed options.

Front hitch ready tractors are not shipped with standard front weight support. A front weight support that bolts to the tractor can be ordered as a factory- or field-installed option (RE326583). The weight support is compatible with suitcase weights (up to 24) and with the 900-kg or 1150-kg (1984-lb or 2535-lb) monster pick-up (monster) weights.

Front weight support is not compatible with front hitch and must be removed before a hitch can be installed.

The sixth rear electrohydraulic SCV is not compatible with front hitch options because of the mid-mount hydraulics for front hitch.

Field-installed hitch options for front hitch/PTO ready tractors:

This attachment provides SCV hydraulic lines from the mid-valve to the front of the machine to control implement functions from the cab.

This kit is for adding only the SCVs to tractors that are not front hitch ready from the factory.

The addition of these front SCVs are required for the use of front hydraulically-powered implement accessories such as a hitch, loader, snow blower, or other accessories. Additional kits (such as software, mounting brackets, and joysticks) may be necessary depending on the accessory and functionality desired.

To fulfill the legal requirements of some areas, a front tow point can be field installed on the front base weight. Mounting hardware must be ordered individually.

This attachment provides SCV hydraulic lines from the mid-valve to the front of the machine to control implement functions from the cab.

7R front hitch ready with front weight support

7R front hitch ready with front weight support  7R front hitch ready frame/hydraulic lines

7R front hitch ready frame/hydraulic lines The front hitch/PTO ready option is ideal for any 7R Series Tractor that may be used for future applications requiring a front hitch or PTO. This option is also beneficial for increased resale value as it provides flexibility for future owners.

This option includes a front casting that accommodates, but does not include a front hitch and front PTO.

In-cab controls for front PTO and front hitch have to be ordered through Parts when ordering the front PTO and front hitch field-installed options.

Front hitch ready tractors are not shipped with standard front weight support. A front weight support that bolts to the tractor can be ordered as a factory- or field-installed option (RE326583). The weight support is compatible with suitcase weights (up to 24) and with the 900-kg or 1150-kg (1984-lb or 2535-lb) monster pick-up (monster) weights.

Front weight support is not compatible with front hitch and must be removed before a hitch can be installed.

The sixth rear electrohydraulic SCV is not compatible with front hitch options because of the mid-mount hydraulics for front hitch.

Field-installed hitch options for front hitch/PTO ready tractors:

Front support with suitcase weights